PET bottle preform mold is an important bottle preform forming equipment. As the global preform market continues to grow, the world's top injection mold manufacturers still dominate the market.

If you want to start your own business or want to develop new preforms for your business, we are here to introduce you to the 10 best plastic preform mold manufacturers and suppliers around the world.

Now, if you are interested in knowing more about the manufacturers of these PET preform molds, we will provide you with the relevant information. For each mold company, we provide an overview of its background, products offered and factory locations.

|

PET bottle preform mold company directory |

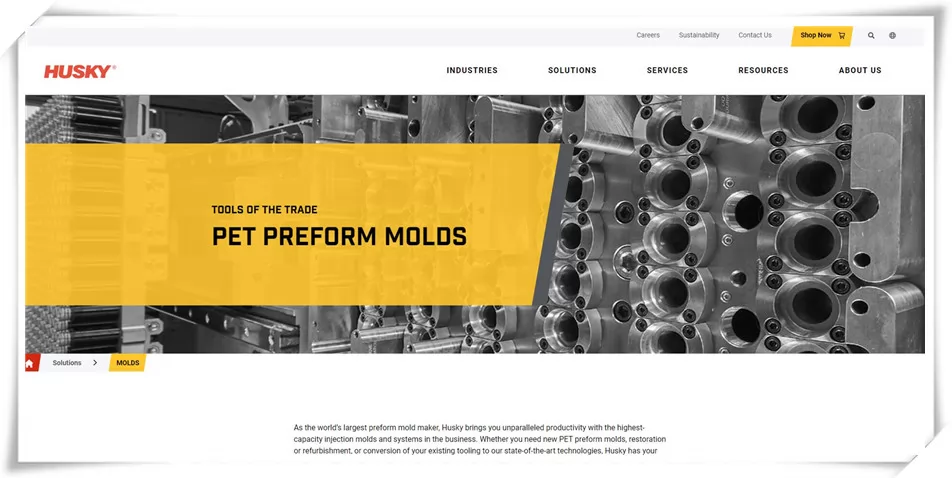

Headquarters: Canada

Company Type: Manufacturer

Website: https://www.husky.co/

Main Products: PET bottle preform mold, beverage bottle cap mold

Company Profile

As the world's largest preform mold maker, Husky brings you unparalleled productivity with the industry's highest-capacity injection molds and systems. Whether you need a new PET preform mold, repair or refurbishment, or converting an existing mold to their state-of-the-art technology, Husky has an injection molding solution for you. They can create every mold configuration imaginable, from 2 to 144 cavities, with the appropriate pitch for your application.

Husky preform mold features:

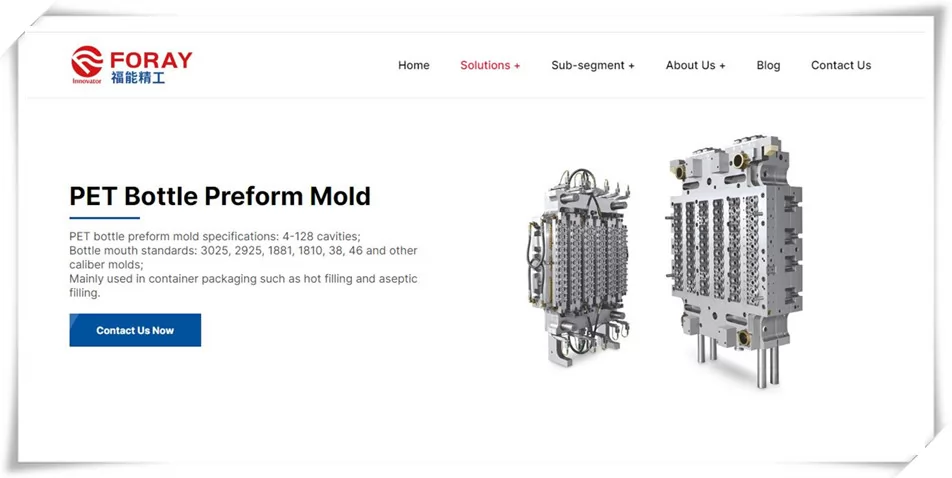

Headquarters: China

Company Type: Manufacturer

Website: https://www.foraypet.com/injection-mould/

Main Products: PET bottle preform mold, medical mold, bottle cap mold

Company Profile

As a Chinese preform mold manufacturer and PET preform mold supplier, Foray specializes in the development and production of environmentally friendly, high-precision, medical and food injection molds, and PET preform molds. They have served more than 80 customers at home and abroad, providing cost-effective preform mold solutions to new and old customers.

Products and perfect after-sales service, all their customized PET bottle preform molds are exported and sold well in Southeast Asia, North and South America, Eastern Europe, the Middle East, Europe, Africa and other countries and regions. It has successfully cooperated with dozens of well-known domestic brand companies. High efficiency, favored by domestic and foreign merchants.

Features of Foray preform molds:

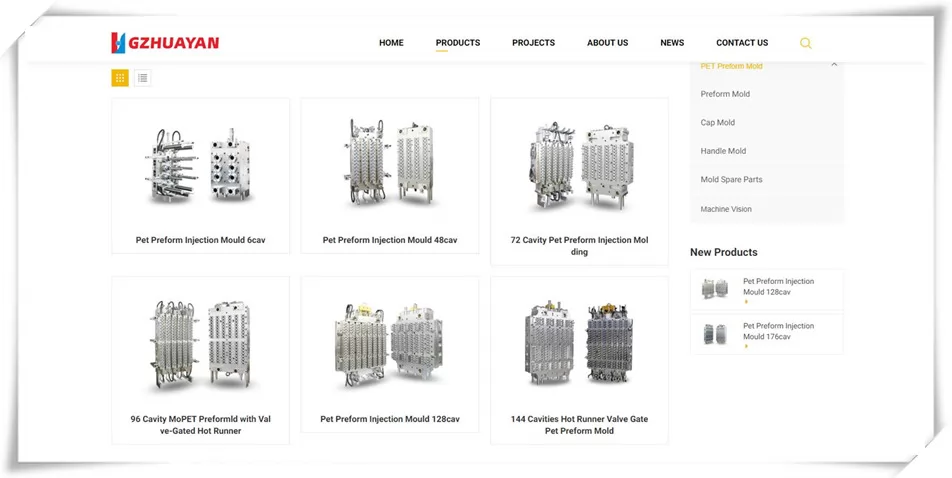

Headquarters: China

Company Type: Manufacturer

Website: https://www.huayanpet.com/

Main Products: PET preform injection molding system, PET preform mold

Company Profile

Guangzhou Huayan Precision Machinery Co., Ltd. specializes in manufacturing PET/PP preform injection systems, including machines and molds, and widely serves PET packaging applications such as beverages, edible oils, food, pharmaceuticals and cosmetics.

The company has about 580 outstanding employees, including experts receiving national government subsidies and senior engineers with master's degrees. They are engaged in 3D design and research and development of primary and secondary PET preform injection systems up to 176cav.

With its good product quality and supreme service, Huayan has sold more than 850 preform systems running around the world. Its customers include Coca-Cola, Pepsi-Cola, Danone Group, Nestlé Group, etc., and top domestic brands include Dali Group, Huiyuan Juice, and Yeshu. water, Yibao water, Wahaha, etc.

Features of Huayan preform mold:

Headquarters: China

Company Type: Manufacturer

Website: https://www.plasticomould.com/

Main Products: Injection mold, preform mold, blow mold

Company Profile

Odin Mold Company specializes in manufacturing plastic molds and custom plastic parts. Odin Mold is a small but smart injection mold factory with advanced equipment and 40 skilled workers.

They have a complete system from design, DFM analysis, mold manufacturing, to product processing, assembly, and inspection.

Their preform mold company has complete design programs (UG, CAD Solid Works, etc.) and injection molding machines (mainly Haitian injection molding machines, from 160T to 1000T. There is a set of gas-assisted injection equipment).

Odin works with customers on design, mold processing, plastic part molding, assembly and quality inspection.

Features of Odin preform molds:

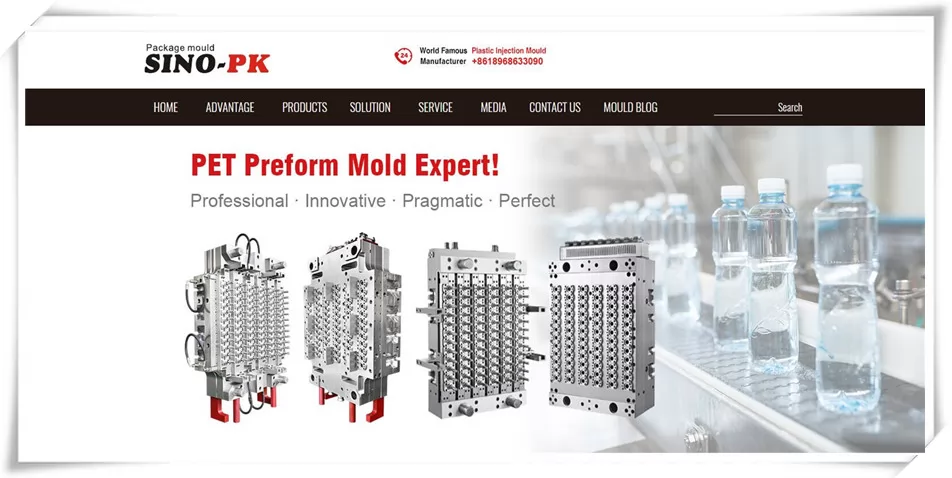

Headquarters: China

Company Type: Manufacturer

Website: https://www.sino-pk.com/

Main Products: PET preform mold, bottle cap mold, IML mold, medical mold

Company Profile

SINOPK PET bottle preform mold is a division of Sino Mold. With 20 years of technology and production experience in PET bottle preform molds, SINOPK has become a world-renowned PET bottle preform mold manufacturer. SINOPK produces more than 200 multi-cavity PET preform molds per year, with the number of cavities ranging from 48 to 144. SINOPK's technological improvements and inheritance over the years have made SINOPK's preform molds more durable, easier to maintain, and more efficient in production.

As an expert in PET preform mold manufacturing, SINOPK has strong R&D capabilities in PET preform mold and bottle cap mold innovation.

Sino Packaging Mold specializes in the production and research of high-quality plastic PET bottle preform molds, bottle cap molds and other packaging molds.

Features of Sino preform mold:

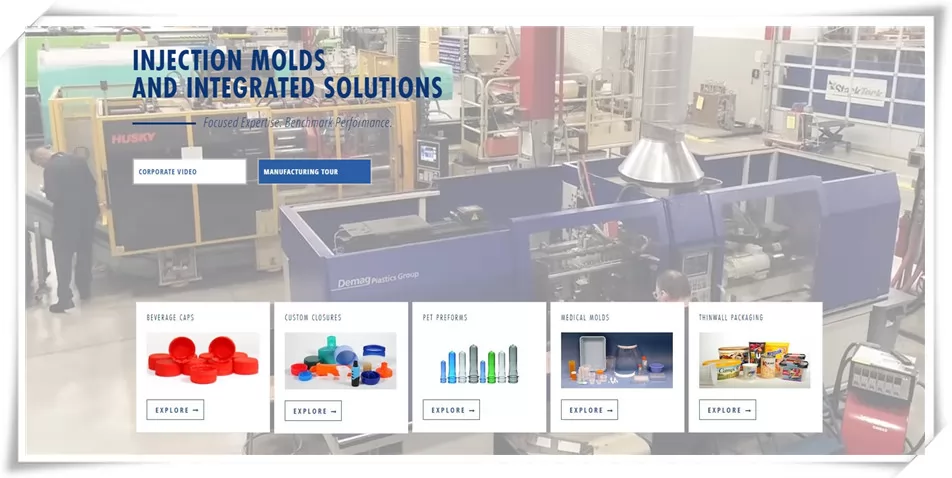

Headquarters: Canada

Company Type: Manufacturer

Website: https://stackteck.com/

Main Products: Bottle preform mold, bottle cap mold, medical mold

Company Profile

StackTeck is a global provider of injection molding and preform molding solutions with innovative technologies for:

Engineering, prototyping and other plastic part development services

Injection molds, frames and rapid product change technology

Automation and intralogistics, including AGVs and inventory systems for smart factories

Their innovative technologies raise many industry standards for high productivity, cost-effectiveness and sustainability in caps and caps, cosmetics, medical, PET preforms, personal care and thin-wall packaging.

Combined with industry-leading capabilities, their dedicated test, service and recovery resources are able to deliver and support large-scale, global, multi-system projects that are initiated and executed to the highest industry standards.

Features of StackTeck preform molds:

Headquarters: China

Company Type: Manufacturer

Website: https://www.king-machine.com/

Main Products: Preform mold

Company Profile

King Machine’s extensive experience in preform mold manufacturing over the years has made them a leading expert in the PET plastic packaging industry.

They currently supply more than 3,000 preform molds to more than 90 countries, and they are constantly expanding.

As one of the leading preform mold manufacturers, King Machine has provided high-quality equipment and excellent services to many customers around the world, such as British-Indian Coca-Cola, Kenyan Aquamist, Tanzania Sayona Jambo, Ugandan Blue Wave, Venezuelan Canaima, etc.

Features of King preform mold:

Headquarters: China

Company Type: Manufacturer

Website: https://go4mould.com/

Main Products: Bottle preform mold, bottle cap mold

Company Profile

Go4mould is a company specializing in the R&D and manufacturing of bottle preform molds. Over the past 20 years, they have invested a lot of energy in updating designs, learning advanced experience, and confirming new theories and designs, creating a unique competitive advantage for the company.

They offer a wide range of innovative PET water bottle preform molds for various occasions. The compact and durable designs of their products are perfect for indoor and outdoor use. Apart from this, Go4mould manufactures PET preform molds for various types of bottles such as water bottles, edible oil bottles, cosmetic bottles and wide mouth jar bottles.

Features of Go4mould preform mold:

Headquarters: China

Company Type: Manufacturer

Website: https://plastic-mold-manufacturer.com/

Main Products: Bucket mold, bottle cap mold, plastic bathtub mold, PET bottle preform mold

Company Profile

YuanCheng Mold has been in the industry of molding for 20 years, thus they have years of manufacturing and designing high quality products such as PET bottle preform mold. The PET bottle preform mold design is a complex process that must take into account many factors. There are many different elements that must come together to create a successful mold, from the shape and size of the bottle to the type of plastic used.

At YC Mold, they understand that each customer has unique needs for PET preform molds. They offer customization services to ensure your mold is designed and manufactured to your exact requirements

Features of YuanCheng preform mold:

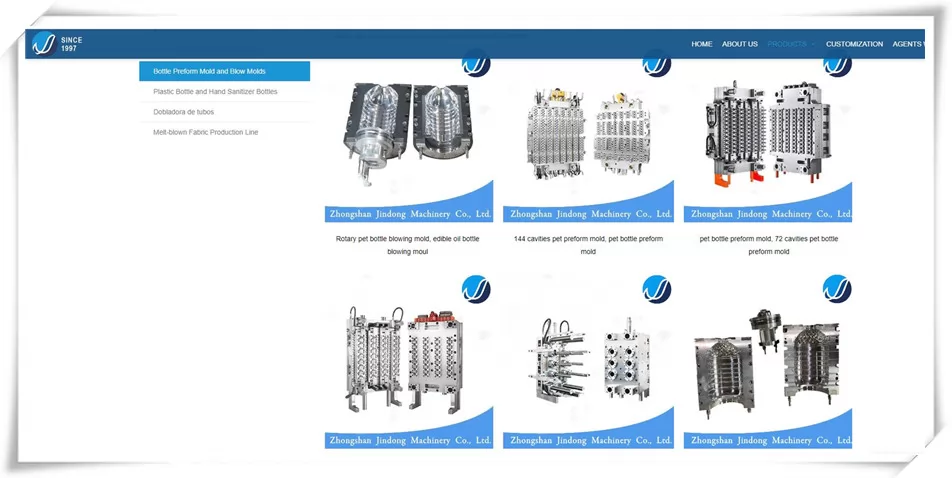

Headquarters: China

Company Type: Manufacturer

Website: https://www.jdblowingmold.com/

Main Products:

Company Profile

Zhongshan Jindong Machinery Co., Ltd. was founded in 1997. The company covers an area of 10,000 square meters. It is a professional plastic mold equipment manufacturing enterprise integrating development, design, manufacturing, technical services and marketing. Since its establishment, the company has been committed to the professional field of PET packaging.

They mainly carry out the whole plant planning of packaging bottles for PET customers, from bottle preform design to bottle blowing molding. Their products include needle valve preform molds and PET bottle blowing molds. They have accumulated about 20 years of design experience and manufacturer.

In addition, Zhongshan Jindong Machinery Co., Ltd. also designs and manufactures PET preform molds, injection molds and blow molding molds. It is the earliest and most professional manufacturer of pneumatic valve hot runner PET bottle preform molds in China.

Features of Jindong preform mold:

When switching to a new PET preform mold supplier for your business, price is closely related to product quality and performance. We hope this article helps you choose the right preform injection mold manufacturer to provide you with reliable products.

If you are willing to import preform molds from China (it is quite cost-effective to customize injection molds from China), then you can save a lot of money and experience the worry-free service of customizing preform molds from China.

If you need related services and quotations, please send an email to contact us. As a well-known injection mold manufacturer in China, we will provide you with the best solutions!