Affordable Water Bottle Preform Making Machine

We are a manufacturer that specializes in providing water bottle preform making machines. Foray's water bottle preform injection molding machine is the perfect solution for producing preforms. Whether you are reselling or buying for your own use, our machines will definitely amaze you! With a leading position in China, you can maximize productivity, minimize part variability, and reduce maintenance, resulting in the lowest total production cost. You can never go wrong ordering a preform making machine from Foray!

| Adapted productivity | Sustainable application | High cost-effective operation | Easy to diagnose and operate |

|---|---|---|---|

| (Efficient and accurate) | (Stable, durable, low noise) | (Energy-saving and reliable) | (Process control, quality traceability) |

| Large injection volume injection molding system | Can carry 24-96 cavity molds | Optimized design of melt part | Leading operating system embedded in SPC application |

| Three-station embryo removal robot | Servo pump technology | Professional valve core drive structure design | BECKOFF control system |

| Special pressure holding cylinder design | Optimized template support design | New energy-saving heating coil | 24-hour response service |

| Proportional valve control | Servo electric or hydraulic melt optional | ||

| 11.5g48 cavity 8S or so |

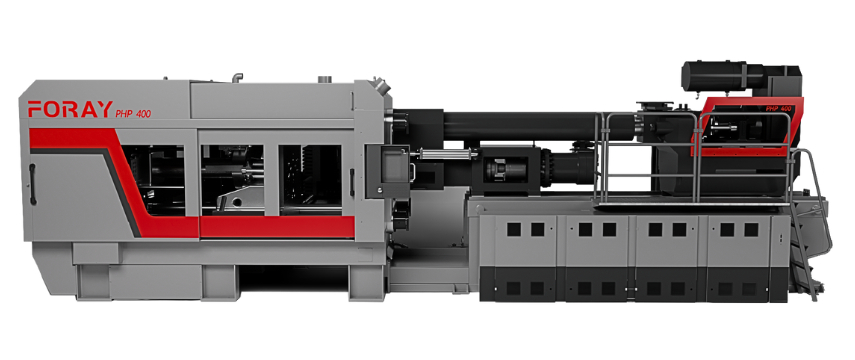

1. ProPET Direct Pressure Series

ProPET direct injection molding machine is a new generation of outstanding models, with a number of practical patented technologies, developed by our R&D team after years of market research and technical research to meet customers' needs for water bottle preforms.

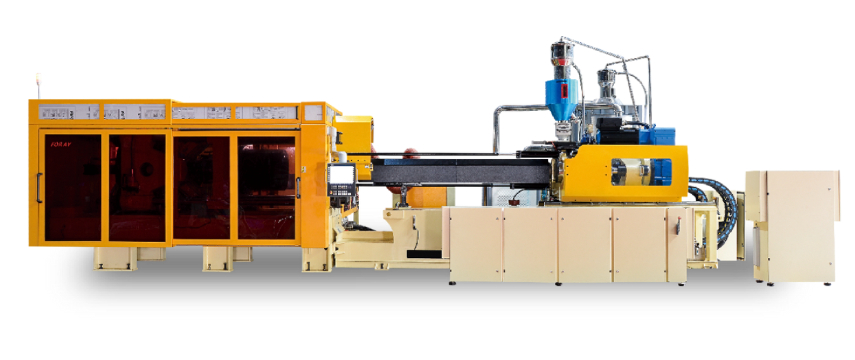

2. F-PET Fast Series

The F-PET high-speed injection molding machine optimizes the unit configuration and is comparable to international high-end equipment in terms of product quality, production efficiency, energy consumption, etc., meeting customers' demands for high quality, high production capacity and high cost performance for mineral water bottle blanks.

3. S-PET Standard Series

This series of bottle cap injection molding machines has the following outstanding advantages: low investment cost, high cost performance, strong practicality, and is particularly suitable for customers with many specifications, many molds, large weights, and medium product output.

4. E-PET Economic Series

E-PET standard injection molding machine adopts efficient screw design and servo systems, our injection molding machines are more efficient and energy-saving than common market models. Ideal for a wide range of industry applications, they cater to customers seeking economic practicality with moderate production volume requirements.

1. Unmatched Production Efficiency

Our injection molding machines are designed for maximum productivity, enabling you to produce high volumes of preforms with remarkable speed. This efficiency helps you meet market demands quickly, keeping your production line running smoothly and profitably.

2. Consistent High-Quality Output

Precision is crucial in preform manufacturing. Our preform-making machine ensures each preform is produced with exacting accuracy, maintaining consistent quality across every batch. This reliability reduces waste and ensures your final products meet the highest standards.

3. Advanced Energy Efficiency

Save up to 30% on energy costs while reducing your environmental footprint. Our preform molding machines are engineered with the latest energy-saving technologies, helping you lower your operational expenses without sacrificing performance.

4. Durable and Reliable Construction

Built with the highest quality materials, our preform-making machines are designed to withstand the demands of continuous operation. Their robust construction ensures long-term reliability, minimizing downtime and maintenance costs by up to 20%.

5. User-Friendly Operation and Maintenance

Our preform-making machines are easy to operate and maintain, even for those new to the technology. With intuitive controls and straightforward maintenance procedures, your team can maximize productivity with minimal training, reducing downtime by up to 15%.

6. Comprehensive Customer Support

We’re not just selling machines; we’re providing solutions. Our dedicated support team is available 24/7 to assist you every step of the way, from installation to ongoing maintenance, ensuring your operations run smoothly and efficiently.

Buy Your Next Water Bottle Preform Making Machine to Make Money

In today's fast-paced and consumer-driven world, the demand for PET preforms, particularly those used in water bottles, has skyrocketed. As the backbone of the beverage industry, high-quality PET preforms are essential in ensuring the integrity, durability, and appeal of the final product. From bottled water to other beverages, these preforms play a crucial role in packaging and distribution. The global rise in bottled water consumption, coupled with a growing preference for safe, portable drinking solutions, has led to an increased demand for water bottle preforms worldwide.

For businesses looking to capitalize on this demand, investing in a Water Bottle Preform Making Machine offers a lucrative opportunity. Whether you're an established manufacturer or a new player in the industry, understanding the intricacies of this equipment and its impact on your operations is key to maximizing profitability. The right machine not only boosts production efficiency but also ensures consistent product quality, which is vital for brand reputation and customer satisfaction.

As consumers continue to prioritize convenience and hygiene, the market for PET preforms has expanded significantly. Water bottle preforms are particularly in demand due to the universal need for bottled water, driven by lifestyle changes, urbanization, and the increasing emphasis on health and wellness. These preforms are the foundation of PET bottles, which are widely used across various industries, including beverages, personal care, and household products.

The growing focus on sustainability has also influenced the PET preform market. Manufacturers are increasingly looking for ways to produce eco-friendly and recyclable PET bottles, further driving the need for advanced Water Bottle Preform Making Machines that can meet these requirements. As the demand for PET preforms continues to rise, investing in state-of-the-art machinery has become not only a profitable venture but also a strategic move to stay competitive in a crowded market.

The preform manufacturing industry offers substantial profit margins, particularly for those who can produce high-quality, consistent products. The initial investment in a Water Bottle Preform Making Machine can yield significant returns, thanks to the growing demand for PET bottles across the globe. These machines enable manufacturers to produce large volumes of preforms quickly and efficiently, reducing production costs and increasing overall profitability.

Moreover, with the right Water Bottle Preform injection molding machine, businesses can achieve a high level of automation, which minimizes labor costs and enhances operational efficiency. This automation not only speeds up production but also ensures that each preform meets stringent quality standards, thereby boosting customer satisfaction and brand loyalty.

A Water Bottle Preform Making Machine is a specialized piece of equipment used to produce PET preforms, the precursor to PET bottles. These machines are integral to the injection molding process, where raw PET material is heated and injected into a mold to form preforms. These preforms are then blown into bottles of various shapes and sizes, depending on the end use.

The machine typically consists of several key components: an injection unit, a clamping unit, a mold system, and an ejector system. The Water Bottle Preform injection molding machine heats the PET material to a molten state before injecting it into the preform mold. Once the preform is shaped, it is cooled and ejected from the mold, ready for the next stage of production.

Modern Water Bottle Preform Making Machines are equipped with advanced technology and automation features that enhance production efficiency and product quality. These machines are designed to handle high-volume production with precision, ensuring that each preform meets exact specifications.

Advanced Technology and Automation Features: Today's machines are equipped with sophisticated control systems that allow for precise adjustments and real-time monitoring of the injection molding process. This automation reduces the need for manual intervention, minimizing errors and ensuring consistent output.

Energy Efficiency and Production Capacity: Modern machines are also designed to be energy-efficient, reducing operating costs while maintaining high production capacity. This is crucial for businesses looking to optimize their operations and reduce their environmental footprint.

Importance of Precision and Consistency: In the preform manufacturing industry, precision and consistency are paramount. Water Bottle preform machines are engineered to produce preforms with uniform wall thickness, weight, and dimensions, which are essential for ensuring the quality and durability of the final product.

Investing in a Water Bottle Preform Making Machine is a significant decision that requires careful consideration of several factors. Understanding your production needs, evaluating machine quality, and considering energy efficiency are all critical to making the right choice.

When selecting a machine, it's essential to match its capabilities with your production requirements. Consider the volume of preforms you need to produce daily, weekly, or monthly, and choose a machine that can meet these demands. Water Bottle Preform molding machines come in various sizes and capacities, so understanding your output needs is crucial to selecting the right equipment.

The quality and durability of the machine are directly tied to the longevity and reliability of your operations. Look for machines made from high-quality materials that can withstand the rigors of continuous production. A durable machine not only reduces downtime but also lowers maintenance costs, contributing to higher overall profitability.

In today's market, energy efficiency is more than just a cost-saving measure; it's a necessity. Machines that consume less energy not only reduce operating costs but also minimize environmental impact. Eco-friendly Water Bottle Preform machines are becoming increasingly popular as businesses seek to align with sustainable practices and meet regulatory requirements.

Understanding the total cost of ownership (TCO) is critical when investing in a Water Bottle preform machine. This includes the initial purchase price, ongoing maintenance costs, and energy consumption. Additionally, explore available financing options, such as leasing or government incentives, to make the investment more manageable.

Investing in a Water Bottle Preform Making Machine can significantly boost your profits by increasing production efficiency, enhancing product quality, and reducing operational costs.

Automation is a key advantage of modern preform machines. By automating the injection molding process, these machines reduce production time and labor costs, allowing you to produce more preforms in less time. This increased output enables you to meet market demand more effectively, leading to higher sales and profitability.

Consistent product quality is essential for maintaining brand reputation and customer loyalty. High-quality preforms lead to better-looking, more durable bottles, which can enhance the perceived value of your products. With a Water Bottle Preform injection molding machine, you can ensure that every preform meets the highest standards, contributing to long-term success.

Modern machines are designed to minimize energy consumption and maintenance needs, resulting in lower operating costs. By investing in a reliable Water Bottle preform machine, you can reduce the frequency of repairs and downtime, leading to significant cost savings over time.

Many companies have successfully leveraged Water Bottle Preform Making Machines to increase their profitability. For example, a leading beverage company invested in advanced preform machinery, which allowed them to double their production capacity while reducing energy costs by 20%. This strategic investment not only boosted their bottom line but also positioned them as a leader in sustainable packaging.

Industry experts agree that investing in a high-quality Water Bottle Preform injection molding machine is a smart move for manufacturers looking to stay competitive. According to one expert, "The right preform machine can transform your production process, allowing you to produce high-quality products at a lower cost. It's an investment that pays off in both the short and long term."

Selecting the right manufacturer is crucial to ensuring you get the best value for your investment. Here are some factors to consider when choosing a manufacturer.

When evaluating potential manufacturers, consider their reputation, experience, and customer service. A manufacturer with a strong track record and positive customer reviews is more likely to provide reliable equipment and support. Additionally, look for manufacturers that offer comprehensive warranties and after-sales support, including spare parts availability.

There are several leading manufacturers of Water Bottle Preform Making Machines, each offering unique features and benefits. Compare the pros and cons of different machines to find the one that best meets your needs. Some manufacturers may offer higher energy efficiency, while others may focus on automation and ease of use.

Investing in a Water Bottle Preform Making Machine is a strategic move that can significantly enhance your production capabilities and profitability. By choosing the right machine and manufacturer, you can ensure consistent product quality, reduce operational costs, and meet the growing demand for PET preforms in the global market.

If you're ready to take the next step in your preform manufacturing journey, contact us today to learn more about our high-quality Water Bottle Preform injection molding machines and how they can benefit your business.