PET bottle preform mold is an important bottle preform forming equipment. As the global preform market continues to grow, the world's top PET preform mold manufacturers still dominate the market.

If you want to start your own business or want to develop new preforms for your business, we are here to introduce you to the 10 best plastic preform mold manufacturers and suppliers around the world.

Now, if you are interested in knowing more about the manufacturers of these PET preform molds, we will provide you with the relevant information. For each mold company, we provide an overview of its background, products offered and factory locations.

A preform mold is a specialized tool used in manufacturing to shape plastic into small, hollow objects called preforms. These preforms are like small bottles or tubes that are later heated and stretched to create the final shape, such as water bottles or other plastic containers.

Think of it like a cookie cutter for plastic. The mold has cavities that determine the preform's size and shape. Hot, melted plastic is injected into these cavities, cooled, and then removed as solid preforms. These preforms are the starting point for making the final product.

In simple terms, a preform mold helps create the building blocks for making plastic bottles and containers.

If you’re looking for a reliable pet preform mould supplier, there are several things to consider to make sure you’re not just getting a mold, but a mold that works for your specific needs. Let's dive in, and I’ll give you the insider tips!

When it comes to PET preform molds, the material is everything. You want to make sure your mold is made from high-quality, durable materials like H13 steel, S136 stainless steel, or 420 stainless steel. These materials are designed to withstand the high temperatures and pressures typical in PET injection molding processes.

Here’s a tip:

Ask the supplier what kind of steel they use. Good suppliers will proudly share this information, and if they don’t—well, that might be a red flag. You want durability and longevity in the mold to ensure fewer maintenance costs and longer operational life.

You probably don’t need a “one-size-fits-all” mold, right? Customization is key, especially if you're looking to produce a unique product or work with a special preform design. A reliable PET preform mold supplier should have a capable engineering team that can design molds specifically for your product’s requirements. The ability to adapt to your needs is a big deal!

Try asking them:

Do they offer custom mold designs?

Can they modify existing molds to fit your needs?

Lastly, let’s talk about price. While it’s tempting to go for the cheapest option, keep in mind that you get what you pay for. The best PET preform molds are a long-term investment, so you want to ensure you’re getting good value for the money. A cheap mold might seem appealing at first, but it could lead to costly issues down the line.

Ask:

Are there any hidden costs, like shipping or handling fees?

Does the mold come with any kind of warranty or guarantee?

Based on extensive market research, here’s a list of the top 10 preform mold suppliers that have a strong reputation for providing high-quality molds and excellent customer service:

| Supplier Name | Specialization | Notable Markets |

|---|---|---|

| Husky Technologies | PET preform molds, injection molding | Global, especially North America & Europe |

| Chengdu Foray Precision Machinery Co., Ltd. | Precision molds for preform injection | Asia, Middle East, Africa |

| Huayan Precision Machinery Co., Ltd | PET preform molds, plastic molding | Asia, Europe |

| Odin Mould Co., Ltd | Preform molds, PET packaging molds | Global, with focus on Asia & Africa |

| Sino Mould Co., Ltd | PET preform molds, custom solutions | Worldwide |

| Stackteck Systems Limited | PET molds, preform molds | North America, Europe, Middle East |

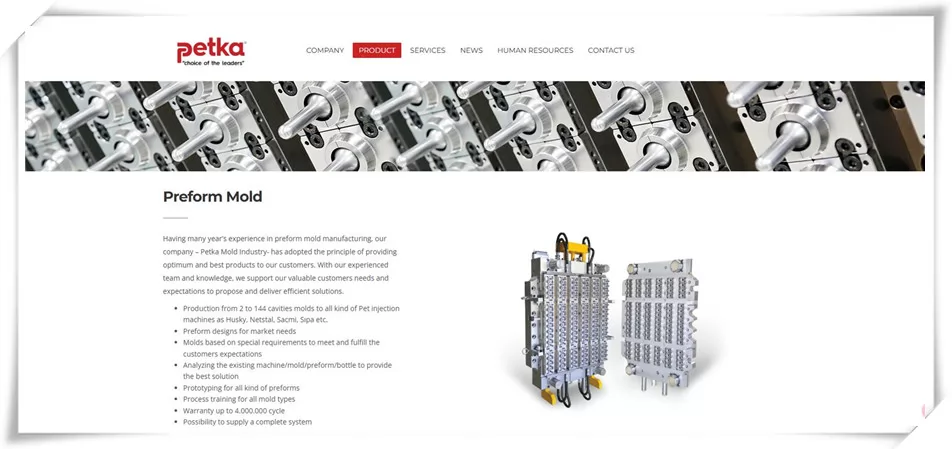

| Petka Mold Industry | PET preform molds, injection molds | Europe, Middle East |

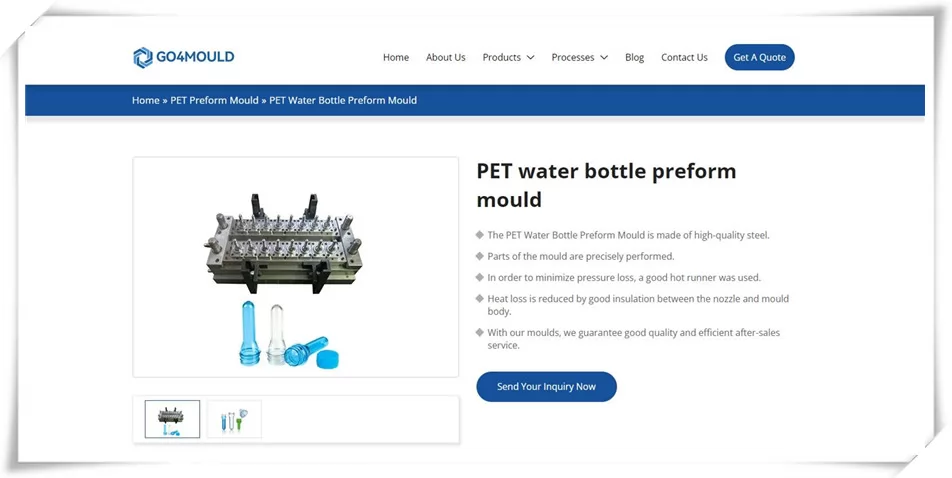

| Go4mould | Plastic molds, preform molds | Global |

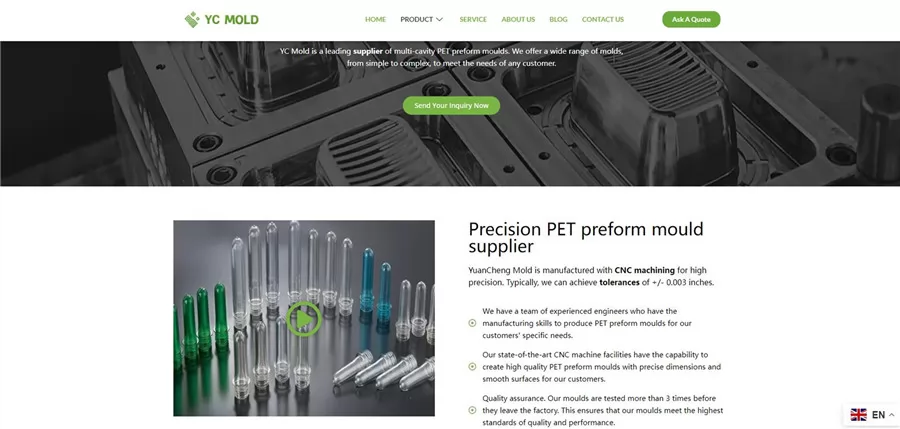

| YuanCheng Mold | PET preform molds, plastic molds | Primarily Asia & North America |

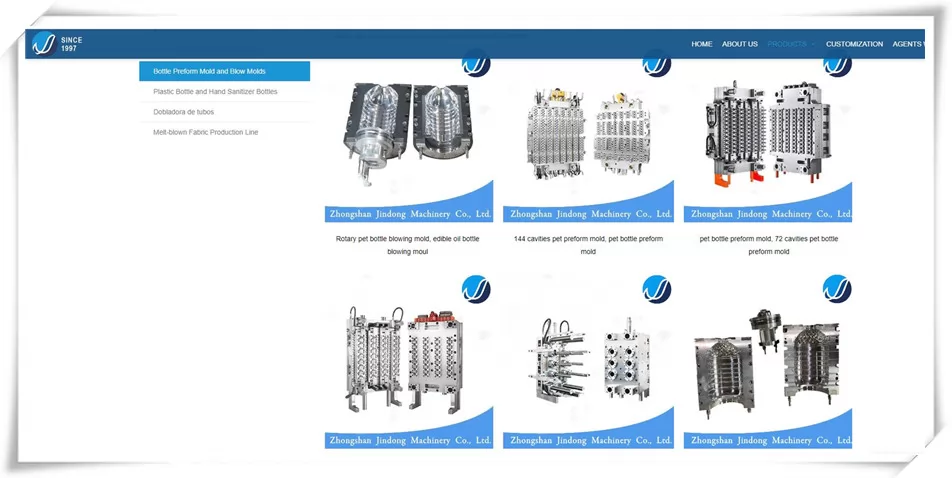

| Zhongshan Jindong Machinery Co., Ltd. | Preform molds, injection molding | Primarily Asia, some European markets |

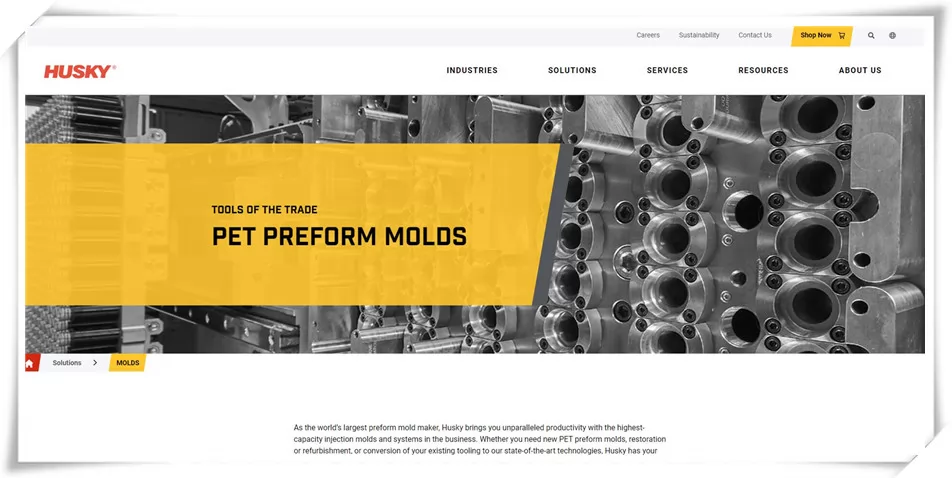

Headquarters: Canada

Company Type: PET preform mold manufacturer

Website: https://www.husky.co/

Main Products: PET bottle preform mold, beverage bottle cap mold

Company Profile

Husky, the world's largest PET preform mold manufacturer, leads the industry with unmatched productivity and cutting-edge technology. Specializing in high-capacity injection molds and advanced molding systems, Husky offers complete solutions for every aspect of preform mold production. Whether you're looking for new PET preform molds, mold restoration and refurbishment, or converting your existing tooling to the latest preform mold factory technology, Husky has you covered.

As a trusted preform mould manufacturer, Husky's molds are engineered to the highest precision standards. Designed for use with both virgin PET and rPET flake or pellets, Husky's solutions contribute to greater sustainability in the manufacturing process. With a focus on future-proofing your business, Husky collaborates with customers to ensure the ideal PET preform injection molding system is tailored to your specific needs—combining the right machines, molds, and auxiliaries.

Husky preform mold features:

Husky’s PET preform molds offer a range of exceptional features designed to optimize performance:

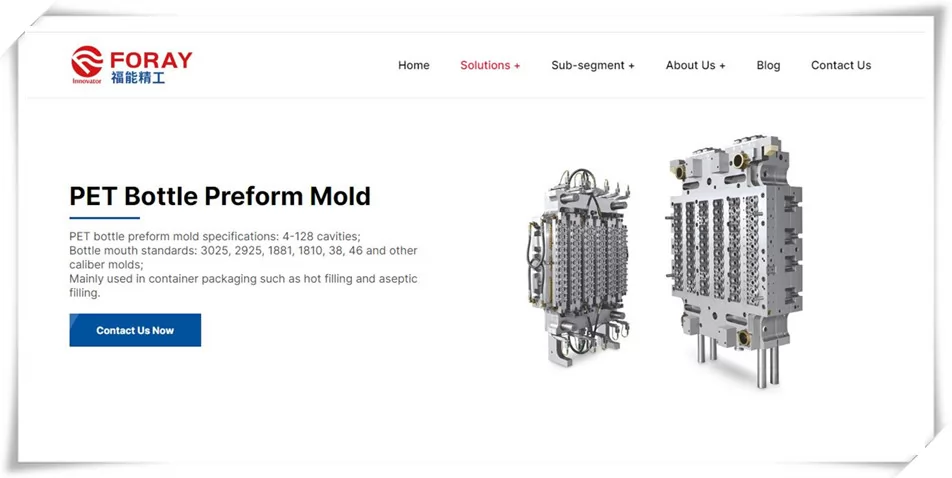

Headquarters: China

Company Type: PET preform mold manufacturer

Website: https://www.foraypet.com/injection-mould/

Main Products: PET bottle preform mold, medical mold, bottle cap mold

Company Profile

As a Chinese preform mold manufacturer and PET preform mold supplier, Foray specializes in the development and production of environmentally friendly, high-precision, medical and food injection molds, and PET preform molds. They have served more than 80 customers at home and abroad, providing cost-effective preform mold solutions to new and old customers.

Products and perfect after-sales service, all their customized PET bottle preform molds are exported and sold well in Southeast Asia, North and South America, Eastern Europe, the Middle East, Europe, Africa and other countries and regions. It has successfully cooperated with dozens of well-known domestic brand companies. High efficiency, favored by domestic and foreign merchants.

Features of Foray preform molds:

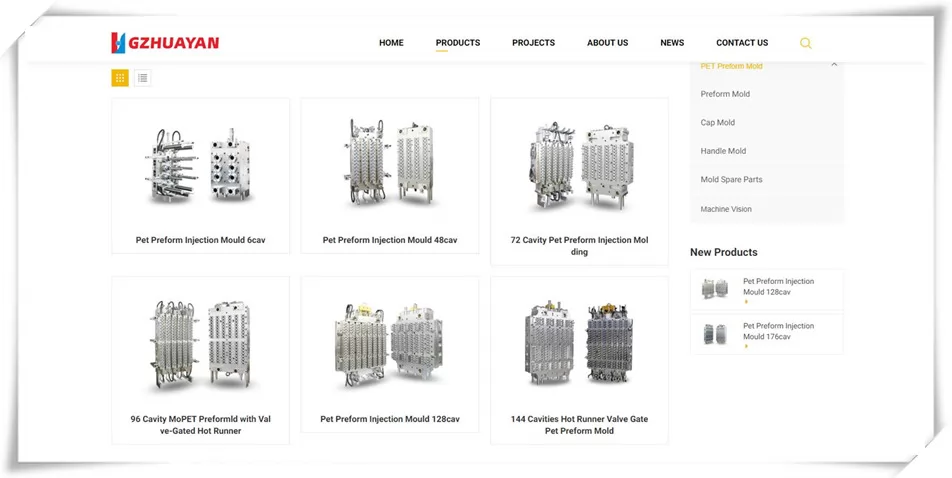

Headquarters: China

Company Type: preform mold manufacturer

Website: https://www.huayanpet.com/

Main Products: PET preform injection molding system, PET preform mold

Company Profile

Guangzhou Huayan Precision Machinery Co., Ltd. is a leading PET preform mold manufacturer specializing in the production of PET/PP preform injection systems, including both the machines and molds. These systems cater to a wide range of PET packaging applications across industries such as beverages, edible oils, food, pharmaceuticals, and cosmetics. With a workforce of around 580 skilled employees, Huayan is home to experts who benefit from the China National Government Allowance, as well as senior engineers with advanced degrees, specializing in 3D design and the development of both one-stage and two-stage PET preform injection systems. The company is capable of producing preform molds with up to 176 cavities.

In 2012, Huayan moved to a state-of-the-art factory located in the Zengcheng Economic & Technology Development Zone. This new facility, which is more than four times the size of their previous location, boasts advanced infrastructure, including high-precision CNC machines and CNC grinding equipment, enabling them to offer enhanced quality and precision in the manufacturing of preform molds. This expansion further strengthens Huayan's position as a trusted preform mold factory, committed to providing innovative, high-quality solutions for global packaging needs.

Features of Huayan preform mold:

Headquarters: China

Company Type: preform mold manufacturer

Website: https://www.plasticomould.com/

Main Products: Injection mold, preform mold, blow mold

Company Profile

Odin Mould Co., Ltd. is a company with many years of experience in manufacturing custom plastic injection moulds and tools, providing high-quality preform injection moulds. It was established in 2002. Odin works with customers from design, mould processing, plastic part moulding, assembly and quality inspection. We can provide you with professional preform mould customization services.

Their preform mold company has complete design programs (UG, CAD Solid Works, etc.) and injection molding machines (mainly Haitian injection molding machines, from 160T to 1000T. There is a set of gas-assisted injection equipment).

Odin works with customers on design, mold processing, plastic part molding, assembly and quality inspection.

Features of Odin preform molds:

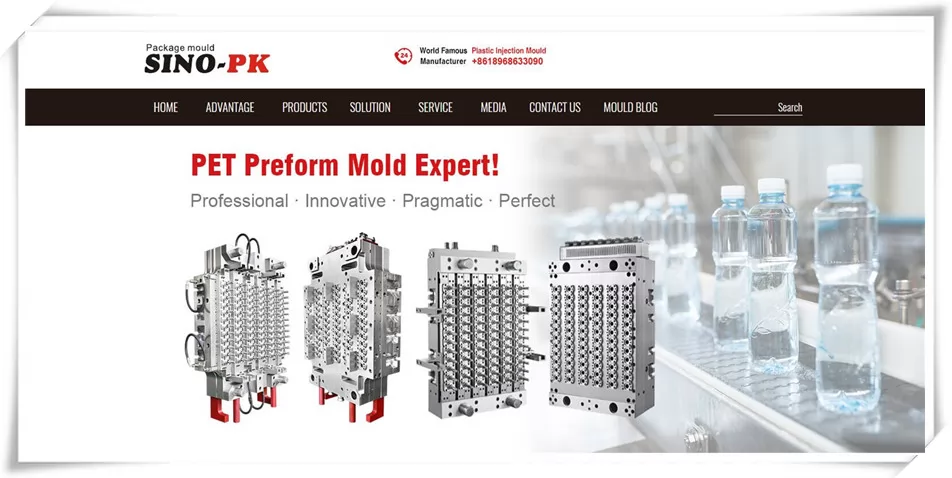

Headquarters: China

Company Type: PET preform mold manufacturer

Website: https://www.sino-pk.com/

Main Products: PET preform mold, bottle cap mold, IML mold, medical mold

Company Profile

SINOPK PET bottle preform mold is a division of Sino Mold. With 20 years of technology and production experience in PET bottle preform molds, SINOPK has become a world-renowned PET bottle preform mold manufacturer. SINOPK produces more than 200 multi-cavity PET preform molds per year, with the number of cavities ranging from 48 to 144. SINOPK's technological improvements and inheritance over the years have made SINOPK's preform molds more durable, easier to maintain, and more efficient in production.

As an expert in PET preform mold manufacturing, SINOPK has strong R&D capabilities in PET preform mold and bottle cap mold innovation.

Sino Packaging Mold specializes in the production and research of high-quality plastic PET bottle preform molds, bottle cap molds and other packaging molds.

Features of Sino preform mold:

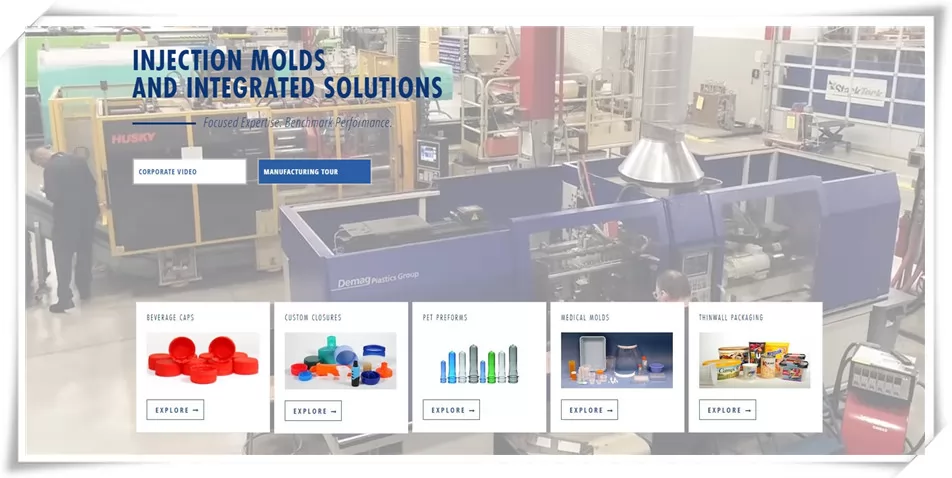

Headquarters: Canada

Company Type: PET preform mold manufacturer

Website: https://stackteck.com/

Main Products: Bottle preform mold, bottle cap mold, medical mold

Company Profile

Stackteck is a mold manufacturer and supplier from Canada. They provide high-quality PET preform molds for local and overseas markets. They are able to provide development services and preform molds from 2 cavities to 144 cavities. Standard and custom mold frames and pitch layouts are available to accommodate a variety of leading platforms and preform applications.

StackTeck PET preform molds utilize innovative ISO hot runner technology to reduce pressure drop, improve cavity-to-cavity balance, significantly reduce color changeover time, and produce lower AA levels than traditional designs while virtually eliminating PET dust.

The molds also utilize KoolTrackTM conformal cooling to increase productivity and patented post-mold cooling technology PiCOOLTM to reduce cycle time and reduce part cost

Features of StackTeck preform molds:

Headquarters: China

Company Type: PET preform mold manufacturer

Website: https://www.petkamold.com/

Main Products: Preform mold,Blow mold

Company Profile

Petka is a preform injection mold manufacturer from China, they were founded in 2005. For many years, Petka has been focusing on the production of PET preform molds, PET blow molds. Their company has a professional, well-equipped and disciplined team to provide the best quality injection mold products to domestic and foreign customers.

Petka has many years of experience in preform mold manufacturing and adheres to the principle of providing customers with the best products. With their experienced team and knowledge, they can provide effective solutions.

If you need a custom preform mold, please click the button to send your requirements.

Features of King preform mold:

Headquarters: China

Company Type: PET preform mold manufacturer

Website: https://go4mould.com/

Main Products: Bottle preform mold, bottle cap mold

Company Profile

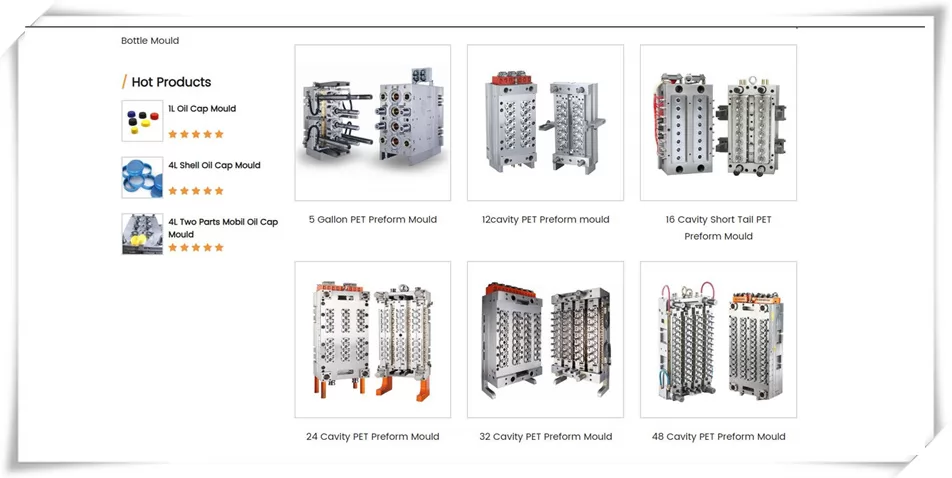

Go4mould is a company specializing in the R&D and manufacturing of bottle preform molds. Over the past 20 years, they have invested a lot of energy in updating designs, learning advanced experience, and confirming new theories and designs, creating a unique competitive advantage for the company.

They offer a wide range of innovative PET water bottle preform molds for various occasions. The compact and durable designs of their products are perfect for indoor and outdoor use. Apart from this, Go4mould manufactures PET preform molds for various types of bottles such as water bottles, edible oil bottles, cosmetic bottles and wide mouth jar bottles.

Features of Go4mould preform mold:

Headquarters: China

Company Type: preform mold manufacturer

Website: https://plastic-mold-manufacturer.com/

Main Products: Bucket mold, bottle cap mold, plastic bathtub mold, PET bottle preform mold

Company Profile

YuanCheng Mold has been in the industry of molding for 20 years, thus they have years of manufacturing and designing high quality products such as PET bottle preform mold. The PET bottle preform mold design is a complex process that must take into account many factors. There are many different elements that must come together to create a successful mold, from the shape and size of the bottle to the type of plastic used.

At YC Mold, they understand that each customer has unique needs for PET preform molds. They offer customization services to ensure your mold is designed and manufactured to your exact requirements

Features of YuanCheng preform mold:

Headquarters: China

Company Type: mold manufacturer

Website: https://www.jdblowingmold.com/

Main Products:

Company Profile

Zhongshan Jindong Machinery Co., Ltd. was founded in 1997. The company covers an area of 10,000 square meters. It is a professional plastic mold equipment manufacturing enterprise integrating development, design, manufacturing, technical services and marketing. Since its establishment, the company has been committed to the professional field of PET packaging.

They mainly carry out the whole plant planning of packaging bottles for PET customers, from bottle preform design to bottle blowing molding. Their products include needle valve preform molds and PET bottle blowing molds. They have accumulated about 20 years of design experience and manufacturer.

In addition, Zhongshan Jindong Machinery Co., Ltd. also designs and manufactures PET preform molds, injection molds and blow molding molds. It is the earliest and most professional manufacturer of pneumatic valve hot runner PET bottle preform molds in China.

Features of Jindong preform mold:

Here is a list of the most popular mold companies in Google 2025

Headquarters: China

Company Type: Bottle preform mold supplier

Main Products:

Company Profile

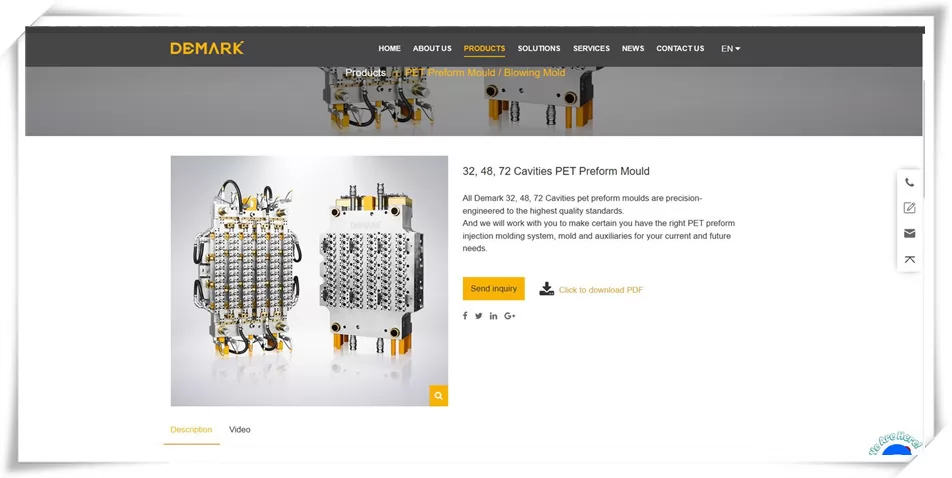

Demark, a leading PET preform mold manufacturer, specializes in producing 32, 48, and 72 cavity PET preform molds. With a team of highly skilled technologists and senior engineers holding master's degrees, Demark excels in 3D mold design and offers expertise that meets the highest industry standards. The company also benefits from the advice of technical committee members and senior professors, who act as consultants to ensure top-quality mold solutions. Demark employs advanced processing equipment and measurement instruments, as well as specialized software, to design, test, and manufacture preform molds that meet the precise needs of the market.

As a trusted preform mold factory, Demark combines cutting-edge technology with superior engineering to deliver durable, efficient bottle preform molds. The company also offers comprehensive after-sales services, including specialized technical training, to ensure customers maximize the potential of their molding systems. Whether you are looking for PET preform molds, advanced preform mold systems, or preform mold components, Demark is dedicated to delivering reliable and cost-effective solutions tailored to your needs.

Features of preform mold:

Headquarters: China

Company Type: Bottle preform mold supplier

Main Products:

Company Profile

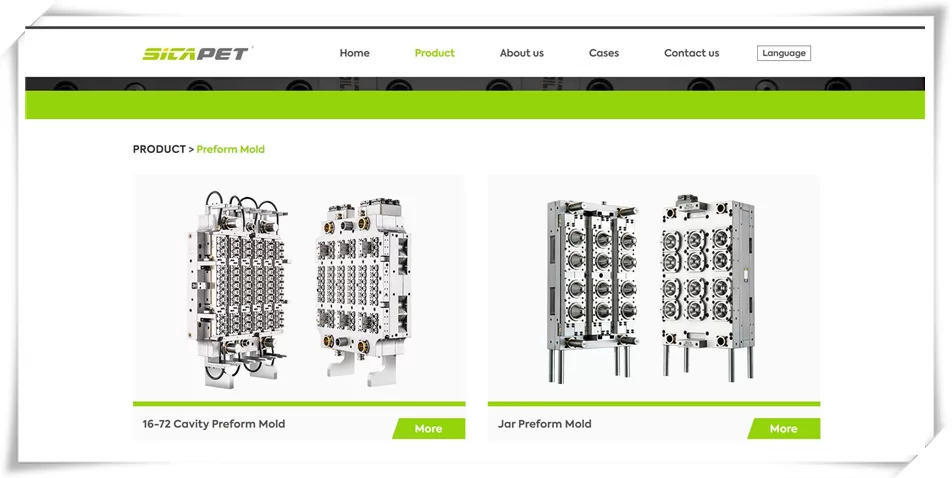

SICA Mold has earned a reputation as one of the most respected PET preform mold manufacturers globally. The company's commitment to quality is rooted in their motto, "To be an artisan is to be a quality manufacturer," which deeply impressed us and led us to begin a partnership. After three years of collaboration, the first batch of molds continues to perform flawlessly, and we are highly satisfied with the results. SICA Mold has truly proven to be the best in the industry.

SICA offers a comprehensive, one-stop solution that addresses every aspect of the PET preform mold process. From preform design to turnkey solutions, SICA is dedicated to providing customized PET preform molds that cater to the unique needs of each customer. Their innovative approach ensures that every mold meets the highest standards of quality and efficiency, making them a trusted partner for businesses worldwide.

Whether you're looking for advanced preform mold systems, bottle preform molds, or specialized PET preform injection molding solutions, SICA Mold is committed to delivering reliable and cost-effective solutions that drive your success.

Headquarters: Canada

Company Type: Bottle preform mold supplier

Main Products: preform mold

Company Profile

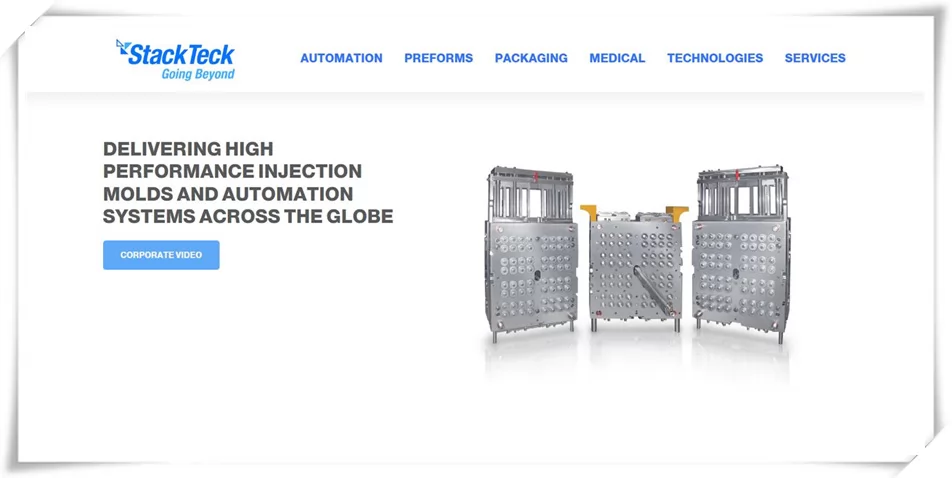

StackTeck is a leading PET preform mold manufacturer, offering a wide range of mold development services with solutions that include molds from 2 to 144 cavities. Their standard and customized mold frames and pitch layouts are designed to accommodate a variety of leading platforms and preform applications, providing flexibility and precision to meet diverse customer needs.

StackTeck’s PET preform molds incorporate cutting-edge ISO hot runner technologies, which offer several advantages over traditional designs. These include reduced pressure drop, improved cavity-to-cavity balance, faster color changeover, and lower AA levels. Additionally, StackTeck molds are designed to virtually eliminate PET dust, enhancing mold longevity and reducing waste.

For improved productivity, StackTeck molds feature KoolTrack™ conformal cooling, which optimizes cooling efficiency and accelerates cycle times. The patented PiCOOL™ post-mold cooling technology further shortens cycle times, ultimately reducing piece part costs and increasing overall production efficiency. These advanced features make StackTeck a trusted partner for businesses looking to improve their PET preform molding systems with high-quality, innovative, and cost-effective solutions.

Headquarters: China

Company Type: Bottle preform mold supplier

Main Products:

Company Profile

Taizhou Shunke Moulding Co., Ltd. is a prominent PET preform mold manufacturer and preform mold factory based in China. Specializing in the design and manufacturing of plastic cap molds, PET preform molds, and blowing molds, the company operates its own dedicated mold factory to ensure the highest quality standards.

At Taizhou Shunke, each project begins with a thorough analysis of product samples or drawings. This comprehensive evaluation includes assessing the feasibility of the molding process, the mold structure, and the movement dynamics, as well as ensuring the compatibility of all related plastic components. The company then offers tailored solutions and custom designs PET preform molds to meet the specific needs of their clients.

Whether you require high-quality PET preform molds or other specialized molding solutions, Taizhou Shunke is committed to providing reliable, cost-effective services that meet the exact requirements of your production processes. With a focus on precision, efficiency, and innovation, they are a trusted partner for businesses seeking durable and customized molding solutions.

Choosing the right preform mold supplier is critical for your business’s success. Here are the key factors to consider when evaluating potential suppliers:

The most important factor in selecting a supplier is the quality of the molds. A reliable supplier should offer high-precision preform molds that meet your production requirements. Look for suppliers that use high-quality materials such as H13 steel or S136 stainless steel, which are known for their durability and resistance to wear.

A supplier’s experience is an important indicator of their ability to meet your needs. Established suppliers with years of experience in the industry are more likely to provide reliable products and excellent customer service. Look for suppliers that have a proven track record of successful projects and positive customer feedback.

Your business might need custom molds to suit specific product designs or unique production lines. A good preform mold manufacturer should offer customization services, allowing you to create molds tailored to your exact specifications. This is especially important for businesses that require specific shapes, sizes, or features in their preforms.

While price shouldn’t be the only determining factor, it is essential to find a supplier that offers competitive pricing without compromising on quality. Be sure to request detailed quotes that outline all costs involved, including shipping, customization, and post-purchase services.

The delivery time and lead time of your preform molds can significantly impact your production schedule. A reliable supplier should provide clear timelines and stick to them. Be sure to inquire about their manufacturing capacity and how long it will take for them to deliver your molds once you place an order.

It’s essential to choose a supplier that provides excellent customer support and after-sales service. This includes product warranties, technical support, and assistance with mold repairs or replacements. Look for suppliers that are easy to communicate with and offer ongoing support throughout the life of the mold.

When switching to a new PET preform mold supplier for your business, price is closely related to product quality and performance. We hope this article helps you choose the right preform injection mold manufacturer to provide you with reliable products.

If you are willing to import preform molds from China (it is quite cost-effective to customize injection molds from China), then you can save a lot of money and experience the worry-free service of customizing preform molds from China.

If you need related services and quotations, please send an email to contact us. As a well-known injection mold manufacturer in China, we will provide you with the best solutions!