About Foray

Top Bottle Cap Making Machine Manufacturer

Foray is one of the most trusted bottle cap injection molding machine manufacturers in China. No matter what kind of plastic cap you need, our bottle cap molding machine can make it happen for you. Foray series high-precision injection molding machines are suitable for the production of multi-cavity mineral water bottle caps, flip caps, threaded rotary caps and other types. Contact us and you will get the bottle cap molding solution that best suits your needs.

| Adapted productivity | Sustainable application | High cost-effective operation | Easy to diagnose and operate |

|---|---|---|---|

| (Efficient and accurate) | (Stable, durable, low noise) | (Energy-saving and reliable) | (Process control, quality traceability) |

| Large injection volume injection molding system | Can carry 24-96 cavity molds | Optimized design of melt part | Leading operating system embedded in SPC application |

| Three-station embryo removal robot | Servo pump technology | Professional valve core drive structure design | BECKOFF control system |

| Special pressure holding cylinder design | Optimized template support design | New energy-saving heating coil | 24-hour response service |

| Proportional valve control | Servo electric or hydraulic melt optional | ||

| 11.5g48 cavity 8S or so |

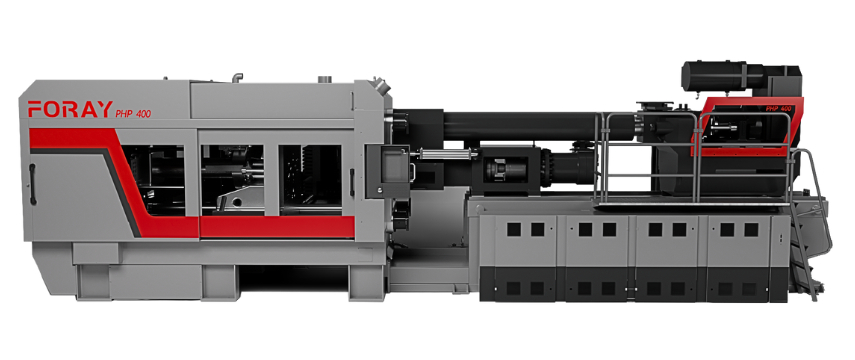

1. ProPET Direct Pressure Series

The ProPET direct pressure injection molding machine is an outstanding new-generation model, equipped with numerous practical patented technologies. Developed by our research and development team through years of market research and technical refinement, it meets customer demands for high-quality bottle caps, high production capacity, ease of maintenance, and sustainable applications.

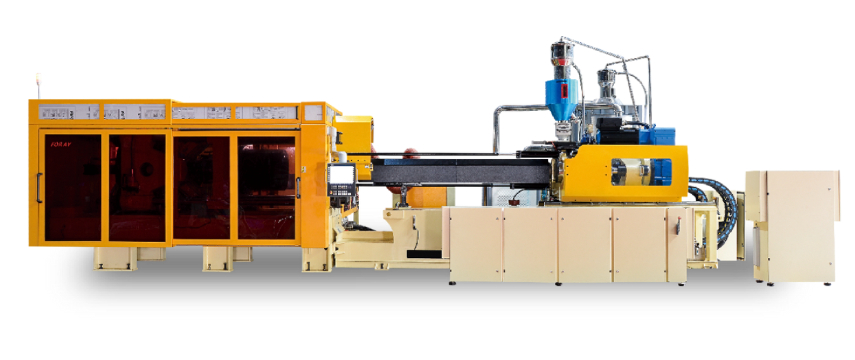

2. F-PET Fast Series

The F-PET high-speed injection molding machine has optimized the unit configuration and is comparable to international high-end equipment in terms of bottle cap product quality, production efficiency, energy consumption, etc. It has excellent product quality and meets customers' demands for high quality, high production capacity and high cost performance of bottle caps.

3. S-PET Standard Series

This series of bottle cap injection molding machines has the following outstanding advantages: low investment cost, high cost performance and strong practicality. It is especially suitable for customers with multiple bottle cap specifications, multiple molds, heavy weight and medium product output.

4. E-PET Economic Series

E-PET standard injection molding machine adopts efficient screw design and servo systems, our injection molding machines are more efficient and energy-saving than common market models. Ideal for a wide range of industry applications, they cater to customers seeking economic practicality with moderate production volume requirements.

Buy Your Next Bottle Cap Making Machine to Make Money

In today's competitive manufacturing landscape, the efficiency and quality of your production process can make or break your business. For companies in industries ranging from beverages to pharmaceuticals, the bottle cap is a critical component that ensures product safety, integrity, and consumer satisfaction. Investing in a high-quality bottle cap making machine is a strategic move that can elevate your production capabilities and enhance your product offerings. This comprehensive guide is designed to help you navigate the complexities of selecting the right bottle cap making machine for your needs.

Whether you are upgrading your current equipment or setting up a new production line, this guide will provide you with the insights and knowledge needed to make an informed decision, ensuring that your investment delivers maximum value and operational efficiency.

A bottle cap injection molding machine(also called plastic bottle cap making machine) is a specialized piece of equipment designed to manufacture plastic bottle caps. Using the injection molding process, this machine melts plastic resin and injects it into a mold cavity where it cools and solidifies into the shape of a bottle cap. These machines are essential for producing high volumes of consistent and high-quality bottle caps used in various industries such as beverages, pharmaceuticals, and household products.

A bottle cap injection molding machine operates through the following steps:

A bottle cap making machine can be used for:

The price of a bottle cap making machine can vary widely depending on several factors such as the machine's production capacity, level of automation, brand, and additional features. On average, you can expect the following price ranges:

It’s important to consider the long-term return on investment (ROI) when evaluating these prices, as higher-priced machines often offer greater efficiency, durability, and lower operating costs.

Choosing the right bottle cap making machine is crucial for ensuring efficient production, high-quality output, and cost-effectiveness. Here are detailed suggestions to guide you through the selection process:

Volume: Assess your production volume needs. Calculate the number of bottle caps you need to produce per hour, day, or month to ensure the machine can meet your demand.

Cap Size and Design: Consider the variety of cap sizes and designs you will be producing. Ensure the machine can handle the specific dimensions and intricacies of your bottle cap designs.

Clamping Force: The clamping force of the machine should be sufficient to hold the mold tightly during injection to prevent any leakage and ensure precise molding.

Injection Capacity: Check the injection capacity, which indicates the amount of plastic the machine can inject into the mold. This should match the size and volume of the caps you plan to produce.

Cycle Time: Shorter cycle times lead to higher production rates. Evaluate the machine's cycle time to ensure it aligns with your production speed requirements.

Fully Automated Systems: These systems require minimal human intervention and are ideal for large-scale production. They include features like automated mold changing, part removal, and quality checks.

Semi-Automated Systems: These require some manual intervention but can be more cost-effective for smaller operations. Determine which level of automation suits your budget and production needs.

Plastic Types: Ensure the machine is compatible with the types of plastic resins you will be using, such as PP, PE, or PET. Compatibility with multiple materials can offer greater flexibility.

Recycling Capabilities: If sustainability is a concern, look for machines that can handle recycled materials efficiently.

Precision and Accuracy: The machine should produce caps with consistent dimensions and quality to ensure proper sealing and fit.

Defect Rate: Consider the machine’s defect rate. Lower defect rates reduce waste and improve overall production efficiency.

Maintenance Requirements: Choose a machine with straightforward maintenance procedures. Check the availability of spare parts and the ease of accessing service support.

User-Friendly Interface: A machine with an intuitive control panel and user-friendly interface can simplify operation and reduce training time for your staff.

Power Consumption: Energy-efficient machines can significantly reduce operational costs. Look for machines with energy-saving features or certifications indicating lower power consumption.

Environmental Impact: Consider machines designed to minimize environmental impact, such as those with lower emissions and waste production.

Manufacturer’s Track Record: Choose machines from reputable manufacturers with a history of producing reliable and durable equipment.

Customer Reviews and Testimonials: Read reviews and testimonials from other users to gauge the machine’s performance and the manufacturer’s customer service.

Technical Support: Ensure the manufacturer offers robust technical support, including remote assistance and on-site service if needed.

Training: Check if the manufacturer provides training for your staff on how to operate and maintain the machine effectively.

To order a bottle cap making machine, follow these steps:

By following these steps and considering the detailed information provided, you can make an informed decision and successfully order a bottle cap making machine that meets your production needs