Precision PET Preform Mould Supplier in China

From design to manufacturing

Best Mould Manufacturer in China

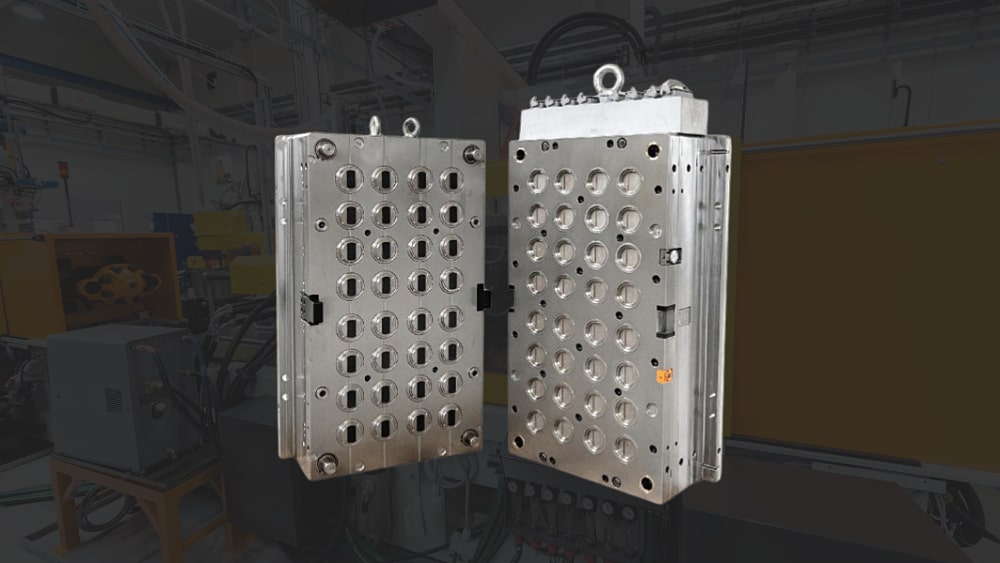

As one of the leading preform mould manufacturers and suppliers in China, Foray brings you unparalleled productivity with 20 years of PET preform mould technology and production experience. Foray provides development services and PET molds from 2 cavities to 144 cavities. Standard and custom mould frames and spacing layouts are available to accommodate a variety of leading platforms and preform applications.

Want to order PET preform moulds quickly and hassle-free? Foray is your best choice!

We offer a variety of PET preform molds, from 1-cavity molds for forming wide can and gallon bottle preforms, to 72-cavity neck preform molds.

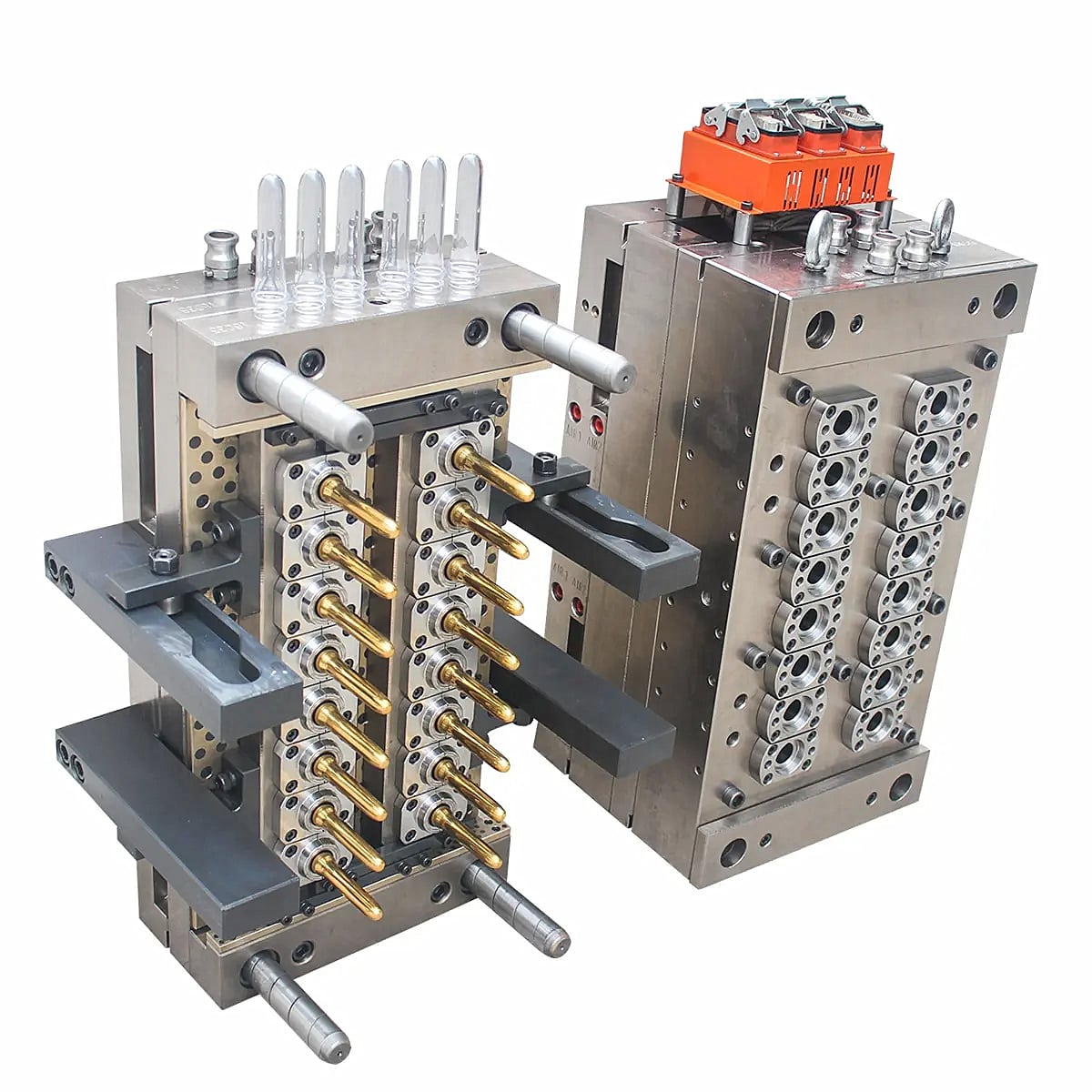

16cavity 30/25 29/25 Beverage Carbonated Drink CSD Plastic Bottle PET Preform Mold

$15,000.00 - $16,000.00

Crafted for precision, this 16 cavity mold is perfect for producing PET preforms for carbonated drinks. It ensures consistency and quality, making it ideal for the beverage industry.

Hot Runner 8/12/16/24/32/48/64 Cavity plastic PET Bottled Water Preform Mould

$10,000.00 - $15,000.00

This hot runner system offers multiple cavity options, ensuring efficient and high-volume production of PET preforms for bottled water. Designed for durability and reliability.

72 Cavities Needle Injection Mold Valve PET Itself-Locking Plastic Preform Mold

$8,000.00 - $12,000.00

Featuring 72 cavities and a needle injection system, this self-locking mold guarantees high precision and efficiency in producing PET preforms. Perfect for large-scale operations.

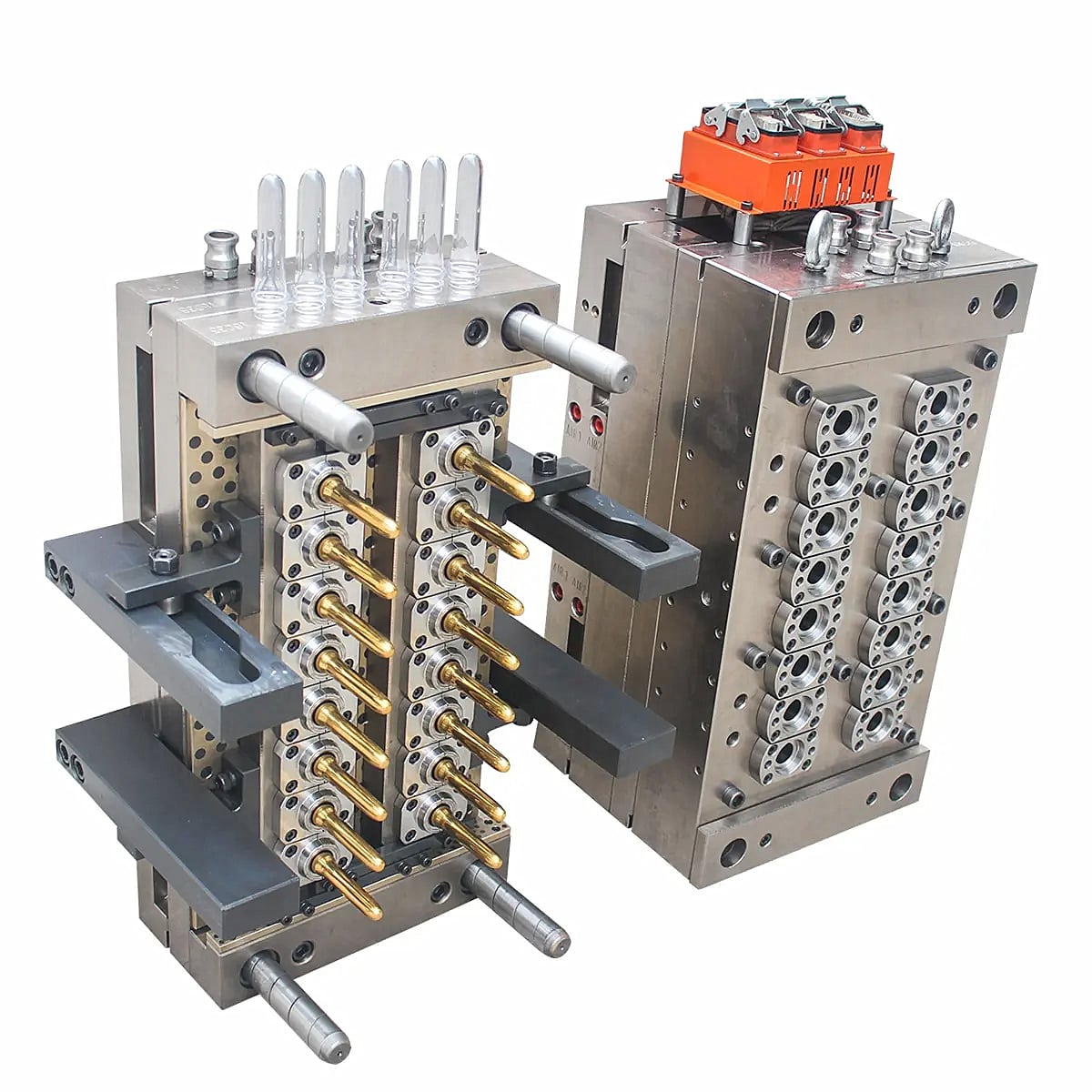

16cavity 30/25 29/25 Beverage Carbonated Drink CSD Plastic Bottle PET Preform Mold

$15,000.00 - $16,000.00

Crafted for precision, this 16 cavity mold is perfect for producing PET preforms for carbonated drinks. It ensures consistency and quality, making it ideal for the beverage industry.

Hot Runner 8/12/16/24/32/48/64 Cavity plastic PET Bottled Water Preform Mould

$10,000.00 - $15,000.00

This hot runner system offers multiple cavity options, ensuring efficient and high-volume production of PET preforms for bottled water. Designed for durability and reliability.

72 Cavities Needle Injection Mold Valve PET Itself-Locking Plastic Preform Mold

$8,000.00 - $12,000.00

Featuring 72 cavities and a needle injection system, this self-locking mold guarantees high precision and efficiency in producing PET preforms. Perfect for large-scale operations.

We offer a variety of PET preform molds, from 1-cavity molds for forming wide can and gallon bottle preforms, to 72-cavity neck preform molds.

| Mold Cavity: | 4 &8 &16 &32 &48 &64 &96 Cavities |

| Core &Cavity Steel | Based on customer’s requirement. |

| Molding Injection System: | Cold Runner System.Hot Runner System |

| Mold Ejection System: | Pin gate, Submarine gate, Valve gate etc |

| Mold Cycle Time: | 10 ~ 18 ± 2 Seconds |

| Plastic material | PP,,PE,HDPE etc. |

| Mold Running: | 1 year Guarantee; Shots guarantee 1 million under the normal operation and period maintenance |

| Mold Delivery Time: | 80 ~ 100 working days to T1 sample delivery |

| Mold Features: | High Polish |

| Mould life | At least 1.5million Shots |

| Delivery time: | 50-60days |

| Packing details: | Standard export packing way |

Designing a preform mold involves several key steps to ensure a high quality and durable product:

Conceptualization and Design

Material Selection

Mold Fabrication

Testing and Refinement

Designing a preform mold involves several key steps to ensure a high-quality and durable product:

Conceptualization and Design: Begin by outlining the specific requirements of the preform, including size, shape, and material considerations. This stage focuses on understanding production needs and defining the precise design.

Material Selection: Choose the appropriate materials for both the mold and preform based on factors like durability, strength, and compatibility with the intended production process. Common mold materials include hardened steel and aluminum for longevity and performance.

Mold Fabrication: Use advanced precision machining techniques such as CNC milling and electrical discharge machining (EDM) to manufacture the mold. Accuracy is critical to ensure the mold produces consistent preforms.

Testing and Refinement: Perform trial runs to evaluate the mold's performance. Assess factors such as dimensional accuracy, ease of use, and cooling efficiency. Refine the mold design based on test results to achieve optimal performance and minimize defects in the final product.

These steps are essential in ensuring the mold can meet production efficiency and long-term durability standards.

About Foray

Foray (Chengdu Foray Precision Machinery Co., Ltd.), headquartered in Sichuan, China, is one of the well-known preform mold suppliers in China. Provide innovative solutions to customers in the preform packaging market to help customers maximize production while reducing operating costs.

☑ OEM/ODM customized solutions to customize your mold.

☑The company has more than 800 employees and a professional R&D team.

☑ The factory area is 15,000㎡+.

Factory Photos

Factory Photos

Factory Photos

Factory Photos

We also want to be your reliable partner to solve your problems and free up your resources.

In the packaging industry, especially for PET bottles, PET preform moulds are essential tools. These molds are used in the first stage of bottle production, helping to shape the raw PET material into preforms, which are then expanded into bottles through a blow-molding process. Selecting the right preform mould is critical for manufacturers aiming to achieve high efficiency, quality, and cost-effectiveness.

This comprehensive guide covers everything you need to know about PET preform moulds, including their design, cost factors, maintenance tips, and how to choose the best pet preform mold manufacturers. Whether you're in the beverage, pharmaceutical, or food packaging industry, understanding the intricacies of preform injection molding will help you make informed decisions.

A PET preform mould is a specialized mold used to shape melted PET plastic into preforms, which are small, test-tube-like pieces. These preforms are later blown into the final shape of bottles, commonly used for packaging drinks, oils, and other liquids. The accuracy and quality of the preform mould directly impact the final product's durability, strength, and appearance.

The primary use of PET preform moulds is to manufacture preforms with precise dimensions and consistent quality, which ensures the strength and efficiency of the final products. Without accurate and reliable moulds, the entire production process can suffer, leading to defects, inconsistencies, and costly waste. In short, PET preform moulds are indispensable for creating the bottles and containers we see every day, from water bottles to cosmetic jars.

The process of manufacturing a PET preform mold is a blend of precision engineering and high-quality materials. Here’s a breakdown of how these moulds are typically made:

Design Phase: The first step is designing the mold according to the specifications required for the preform. This involves determining factors such as the preform's weight, shape, and the neck finish. Specialized CAD (Computer-Aided Design) software is used to create a blueprint of the mold.

Material Selection: Mold-making materials are selected carefully, focusing on strength, durability, and heat resistance. Common materials include hardened steel and sometimes aluminum for less demanding projects. These materials ensure that the mold can withstand repeated high-pressure injections and high temperatures during production.

Mold Fabrication: Once the design is finalized, the actual fabrication process begins. CNC (Computer Numerical Control) machining is commonly used to cut the steel into the desired mold shape with extreme precision. This step is crucial because even minor errors in fabrication can lead to defects in the final preform.

Heat Treatment: The steel used in the mold is often heat-treated to increase its hardness and durability, ensuring it can withstand the rigors of the production process without wearing out quickly.

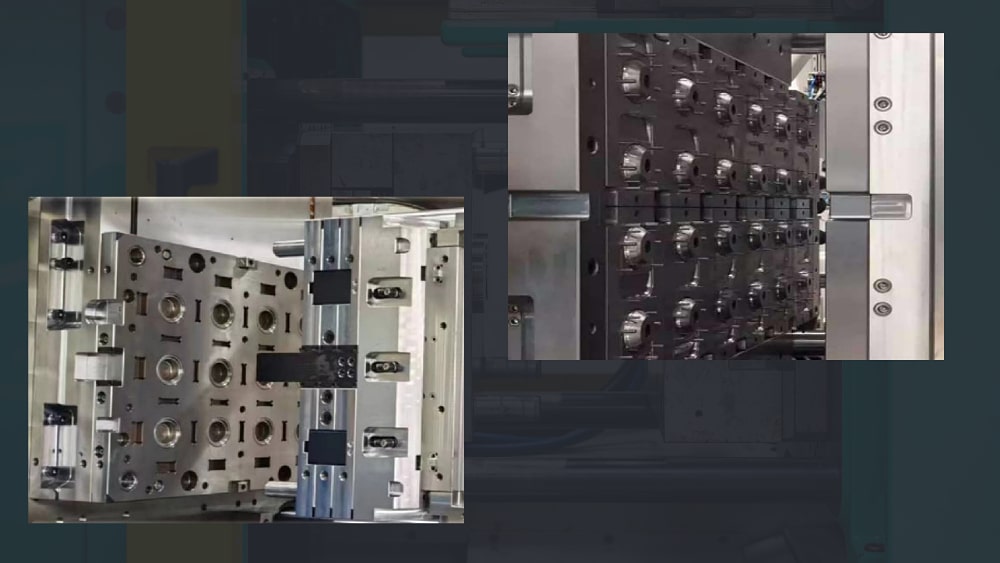

Polishing and Finishing: The mold cavity is polished and finished to ensure a smooth surface. Any roughness or imperfections in the mold can transfer to the PET preform, affecting its quality.

Assembly: The mold components are then assembled, and the mold is tested to ensure it meets the required specifications. Adjustments are made as needed to guarantee optimal performance.

Testing and Fine-Tuning: Before the mold is mass-produced, it undergoes rigorous testing to ensure it produces preforms that meet industry standards. This step is crucial for minimizing future defects and ensuring consistent quality.

There are several types of PET preform moulds designed to cater to different applications and production requirements:

Single Cavity Moulds: These are used for low-volume production. They feature just one cavity, so only one preform is produced per cycle. While slower, single-cavity moulds are more affordable and suited for smaller manufacturing operations or testing new designs.

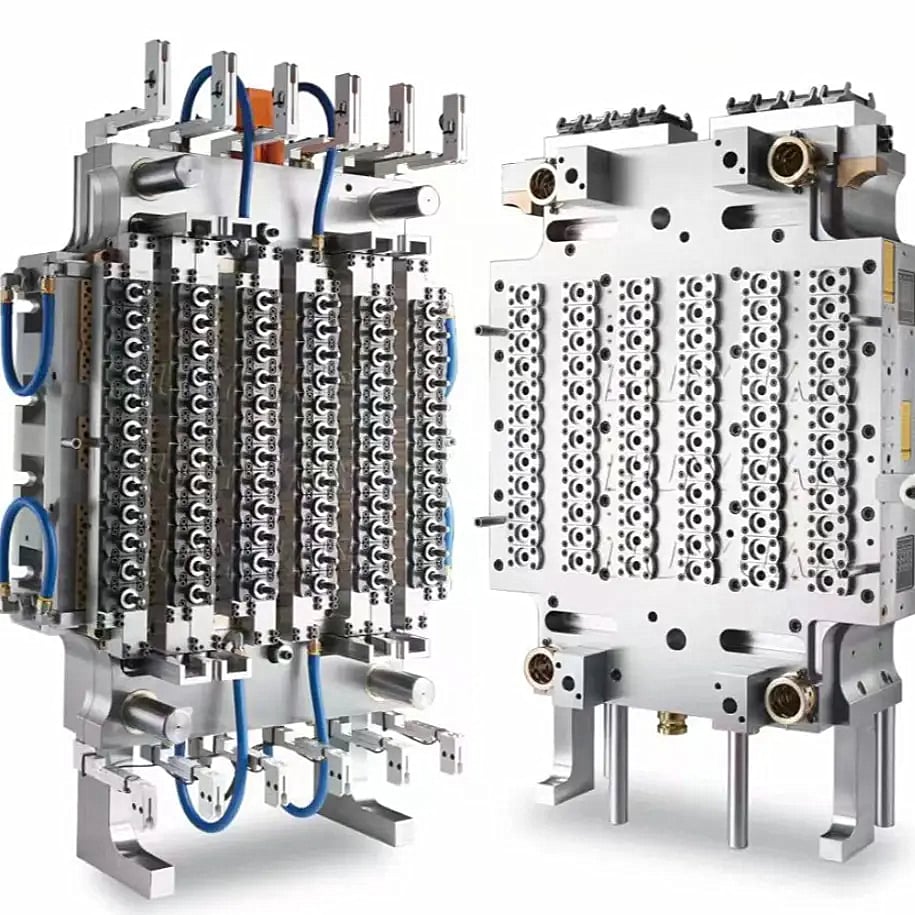

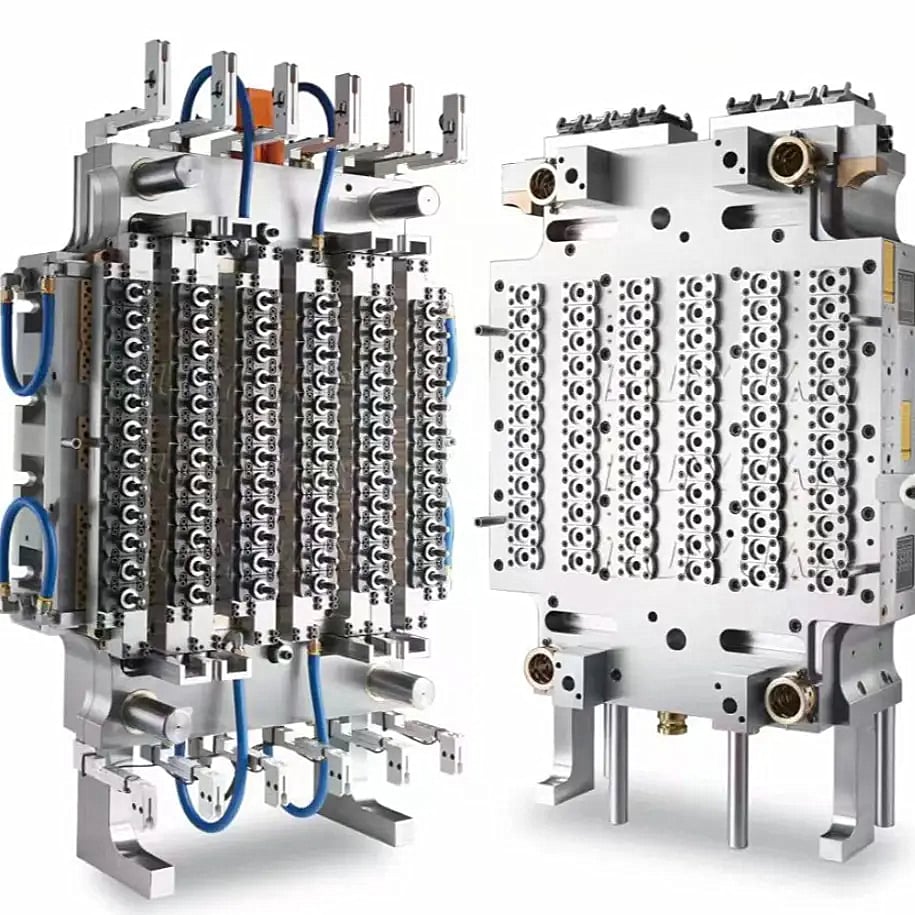

Multi-Cavity Moulds: These moulds have multiple cavities, often ranging from 4 to 72 or more, allowing for the production of multiple preforms per cycle. Multi-cavity moulds are commonly used in large-scale manufacturing where speed and high output are critical.

Hot Runner Moulds: Hot runner moulds are designed to reduce waste during production. The plastic material in the runner system is kept molten, which eliminates the need to discard cooled, unused plastic between cycles. This type of mould enhances efficiency and reduces material costs.

Cold Runner Moulds: In contrast to hot runner systems, cold runner moulds allow the plastic to cool in the runner, resulting in some material waste. These are typically less expensive than hot runner moulds but may require more material to compensate for the waste.

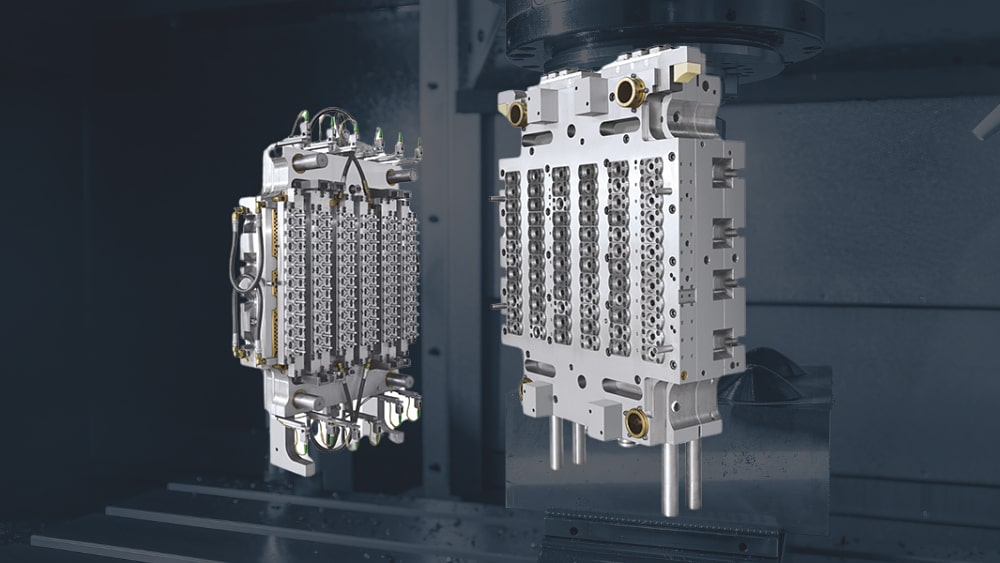

Stack Moulds: Stack moulds are designed for extremely high-output production environments. They consist of multiple mould layers, effectively doubling or tripling the number of preforms that can be produced in a single cycle. However, they require more complex machinery and higher levels of maintenance.

PET preform moulds must be made from materials that can withstand the stresses of repeated use at high temperatures and pressures. The most common materials used are:

Hardened Steel: Steel is the most popular material for PET preform moulds due to its strength, durability, and ability to resist wear and tear. It can endure the heat and pressure of the injection molding process for extended periods without deforming or losing precision.

Stainless Steel: In some cases, stainless steel is preferred for its corrosion resistance, particularly in environments where the mould is exposed to moisture or chemicals.

Aluminum: Although less durable than steel, aluminum moulds can be used for low-volume production or prototyping due to their lower cost and faster machining times.

Copper Alloys: Copper alloys are sometimes used for specific parts of the mould, like cores and cavities, due to their excellent thermal conductivity, which helps speed up the cooling process.

Designing a PET preform mold involves several key considerations to ensure the final product meets both functional and aesthetic requirements:

Preform Wall Thickness: The wall thickness of the preform must be uniform to ensure even blowing during the molding process. Variations in thickness can lead to weak spots or deformation in the final bottle.

Cooling System: Efficient cooling is crucial for reducing cycle times and increasing production output. Moulds are designed with internal cooling channels that allow water to flow through, speeding up the cooling process of the PET material.

Neck Finish: The neck finish of the preform must be precise, as it determines the type of cap or closure that can be used on the final bottle. Moulds must be designed to create neck finishes that meet industry standards.

Ejection System: After the preform is formed and cooled, it must be ejected from the mold without damage. An efficient ejection system ensures the preform is released smoothly and without defects.

Runner System: The design of the runner system (whether it’s a hot or cold runner) affects material usage and waste. Hot runner systems are more efficient, reducing waste and improving cycle times.

Cavity Layout: The layout of the cavities in the mold is essential for optimizing production efficiency. Moulds with more cavities can produce more preforms per cycle, but they require more complex machinery and higher levels of maintenance.

When selecting a PET preform mould, there are several factors to consider:

Production Volume: Determine whether you need a single-cavity or multi-cavity mould based on your production volume. Multi-cavity moulds are best for high-output operations, while single-cavity moulds may be sufficient for smaller runs.

Material Quality: The quality of the mould materials will affect its longevity and performance. Investing in a high-quality steel mould will reduce the need for frequent repairs or replacements.

Customization Needs: If you require specific neck finishes or preform shapes, ensure the mould manufacturer can accommodate your customization needs.

Cooling System Efficiency: An efficient cooling system can significantly reduce cycle times and improve productivity. When choosing a mold, ensure the cooling channels are designed to evenly cool the preforms without causing defects or warping.

Hot vs. Cold Runner Systems: Decide whether you need a hot or cold runner system based on your production goals and material usage. Hot runner molds reduce material waste and speed up production, but they are more expensive upfront. Cold runner systems, while cheaper, may lead to higher material waste and longer cycle times.

Maintenance and Durability: Choose a mold that is durable and requires minimal maintenance. High-quality steel molds with proper surface finishing will last longer, reducing the frequency of repairs or replacements, ultimately saving costs over time.

Cost vs. Quality Balance: While it’s tempting to go for the cheapest option, investing in a higher-quality mold will save money in the long run by minimizing defects, downtime, and repairs.

The price of a PET preform mould can vary widely depending on several factors, including the number of cavities, the type of runner system, the material used, and the complexity of the design. Here's a general breakdown of the costs:

Single-Cavity Moulds: These are the least expensive option, typically ranging from $5,000 to $10,000, depending on the materials used and design complexity.

Multi-Cavity Moulds: Multi-cavity moulds can range anywhere from $20,000 to $150,000 or more. The more cavities the mold has, the higher the price. Moulds with 72 cavities or more are at the higher end of the price spectrum.

Hot Runner Moulds: Hot runner systems are more expensive due to the technology involved, with prices generally ranging from $30,000 to $200,000. This type of mould is an investment in long-term production efficiency, as it reduces material waste and speeds up cycle times.

Cold Runner Moulds: Cold runner moulds are more affordable, typically costing between $10,000 and $80,000. However, the increased material waste and longer cycle times can make them more expensive to operate in the long run.

Stack Moulds: These are the most complex and expensive, often costing $150,000 to $500,000 or more. They are used in high-output production environments and can produce multiple preforms per cycle, which justifies the high upfront cost.

Several factors influence the pet preform mould price:

Cavity Count

Molds with more cavities (e.g., 32-cavity or 64-cavity molds) are more expensive, but they allow for higher production capacity, making them cost-effective in high-volume environments.

Runner System

Hot runner molds are more expensive upfront but reduce material waste and increase efficiency, lowering long-term operational costs. In contrast, cold runner molds have a lower initial cost but higher operational expenses due to material waste.

Mold Material

The type of material used in the pet preform mold design plays a significant role in determining the price. Molds made from hardened steel or other durable materials are more expensive but offer a longer lifespan and higher resistance to wear and tear.

Customization

If your business needs customized preform designs, such as unique thread patterns or specific dimensions, the cost of the mold will increase. Custom molds take longer to design and require more advanced engineering.

Reducing the cost of PET preform moulds without compromising on quality can be challenging, but there are several strategies you can consider:

Optimize Mold Design: Work closely with the mold designer to create a design that minimizes material waste and cycle time. Efficient cooling channels and streamlined ejection systems can significantly reduce production costs over time.

Use Multi-Cavity Moulds: While the initial investment in multi-cavity moulds is higher, they allow for higher production rates, which can help lower the cost per preform. This is particularly beneficial for large-scale operations.

Consider Hot Runner Systems: Hot runner moulds reduce material waste by keeping the plastic in the runner system molten between cycles. Although the upfront cost is higher, you’ll save on material costs and reduce waste over the long term.

Invest in High-Quality Materials: Choosing high-quality steel or other durable materials for the mould will reduce maintenance and replacement costs over time. While it may increase the initial investment, it can save money in the long run by extending the life of the mould.

Regular Maintenance: Proper maintenance of the mould is essential for keeping costs low. Regular cleaning, polishing, and inspection will prevent wear and tear, ensuring the mould remains in good condition for a longer period.

Bulk Orders: If you're producing a large volume of preforms, ordering in bulk from a manufacturer may result in cost savings. Many suppliers offer discounts for large orders, which can help lower the overall production cost.

Choosing the right PET preform mould depends on your specific production needs, including volume, budget, and customization requirements. Here’s a step-by-step guide to help you make the best decision:

Design of the Preform Mould

The design is paramount to the efficiency of the production line. Well-designed molds reduce cycle times, enhance cooling, and ensure even material distribution in the preform. It's also crucial that the pet preform mold design allows easy integration with your production system, minimizing downtime.

Number of Cavities

The number of cavities in a mold directly affects production output. More cavities allow for the creation of multiple preforms in a single cycle, increasing production efficiency. For high-volume production, consider molds with multiple cavities to enhance output.

Material

Quality materials like hardened steel are critical for the mold's longevity. Cheaper molds may reduce upfront costs but often wear out quickly, leading to expensive downtime and replacement needs. The durability of the preform mould should match your production demands.

Cooling System

Efficient cooling is essential for fast production. Molds with advanced cooling channels reduce cycle times, allowing for quicker production without compromising the quality of the preform.

China is one of the leading producers of PET preform moulds, known for its competitive pricing and manufacturing expertise. Here’s how to find a reliable supplier:

Search Online B2B Platforms: Websites like Alibaba, Made-in-China, and Global Sources are popular platforms where you can find a wide range of PET preform mould manufacturers. These platforms allow you to compare prices, check reviews, and communicate directly with suppliers.

Attend Trade Shows: Trade shows such as Chinaplas (China International Plastics and Rubber Exhibition) are excellent places to meet manufacturers in person, see product samples, and discuss your specific requirements.

Consult Industry Experts: If you’re new to sourcing from China, consider working with a sourcing agent or consultant who can help you navigate the market and find a trustworthy manufacturer.

Verify Credentials: Before making any deals, verify the manufacturer’s credentials. Check their experience in the industry, production capabilities, and quality control processes. Request samples or visit the factory if possible to ensure they meet your standards.

Ask for References: A reputable manufacturer should be able to provide references or case studies of past clients. Speaking to other businesses that have worked with the supplier can give you valuable insight into their reliability and the quality of their products.

Sourcing PET preform moulds from China has several advantages:

Cost-Effective Pricing: Chinese manufacturers offer competitive pricing, making it possible to get high-quality molds at a fraction of the cost compared to Western countries.

Advanced Manufacturing Capabilities: Many Chinese manufacturers use state-of-the-art equipment and technology, ensuring that the moulds produced are precise and durable.

Customizability: Chinese manufacturers are often willing to work closely with clients to create customized moulds that meet specific design and production needs. This flexibility is a major advantage for companies requiring unique preform designs.

Scalability: Chinese manufacturers have the capacity to handle large orders, making them ideal for businesses looking to scale their production.

Fast Production Lead Times: With a large number of manufacturers to choose from, you can often find suppliers that can meet tight deadlines and deliver moulds quickly.

Finding affordable, high-quality preform moulds involves thorough research and careful selection. Here are some tips:

Compare Multiple Suppliers: Don’t settle for the first quote you receive. Request quotes from several manufacturers and compare them based on price, quality, and lead times.

Look for Discounts or Bulk Pricing: Some manufacturers may offer discounts for bulk orders or long-term contracts. Negotiate pricing terms that fit your budget.

Review Manufacturer Portfolios: Check for reviews and case studies that demonstrate the quality of their products. High-quality manufacturers often have portfolios showcasing their work and satisfied clients.

Balance Price and Quality: While it’s tempting to choose the cheapest option, focus on finding a balance between affordability and durability. An investment in a higher-quality mold will pay off in the long run by reducing defects, maintenance, and downtime.