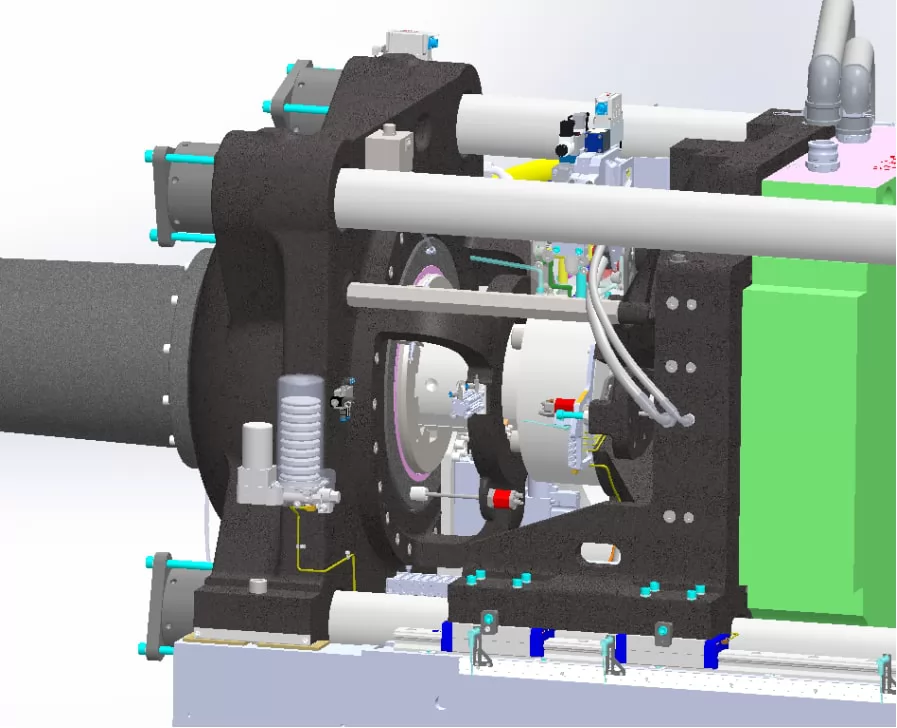

Patents are an important measure of an enterprise's innovation capabilities and a driving force for its sustainable development. For this reason, FORAY Precision has always maintained the spirit of craftsmanship in scientific research and innovation, and has worked hard to achieve more than 30 patents. On August 25, 2023, On the same day, FORAY Precision once again won the invention patent certificate issued by the State Intellectual Property Office for "a high-pressure mold clamping device for direct presses", which protects the sustainable application of FORAY's injection molding system and achieves cost reduction and efficiency improvement for customers.

With the continuous iteration of the injection molding machine market, direct-pressure injection molding machines are favored by the market. Its unique linear guide rail clamping structure improves equipment operating efficiency, reduces the loss of structural parts, and extends the service life of equipment. However, when the clamping structure of the existing direct-pressure injection molding machine equipment on the market is operated frequently and at high intensity, it only relies on the wear-resistant ring to support the high-pressure clamping device, which will easily cause oil leakage or wear of structural parts, resulting in high maintenance costs. It will also be very high, and the machine needs to be shut down to disassemble and repair the mold clamping structure. Shutdown will cause economic losses, or product delivery delays and other unfavorable situations.

FORAY Precision's patented invention technology of "a high-pressure clamping device for direct presses" optimizes the clamping guide positioning support structure and adds the application of guide rod and seal combination technology, which will change various problems that occur in direct presses on the market. Bring long-term benefits to customers.

► Solve problems such as oil leakage and structural parts wear during equipment operation, ensure smooth operation of equipment and improve production efficiency under high frequency and high pressure.

► Equipment maintenance and repair are more convenient. It supports partial disassembly and maintenance of the equipment without disassembling the whole machine. In a convenient and efficient manner, high-frequency maintenance can be achieved, the service life of important mold clamping devices can be extended, or it can be operated continuously for a long time.

► Directly improve the cost-effectiveness of direct-pressure injection molding machine equipment. If the maintenance and replacement cycle of important mold-locking structural parts of direct-pressure injection molding machines in the market is about once every three years, the replacement theory of mold-locking structural parts of injection molding machines applied with patented technology can be extended to once every six years. Moreover, the replacement cost of the clamping structural parts of the injection molding machine using the patented technology is only 1/3 of that of the market machine, which greatly reduces the later maintenance costs for customers.