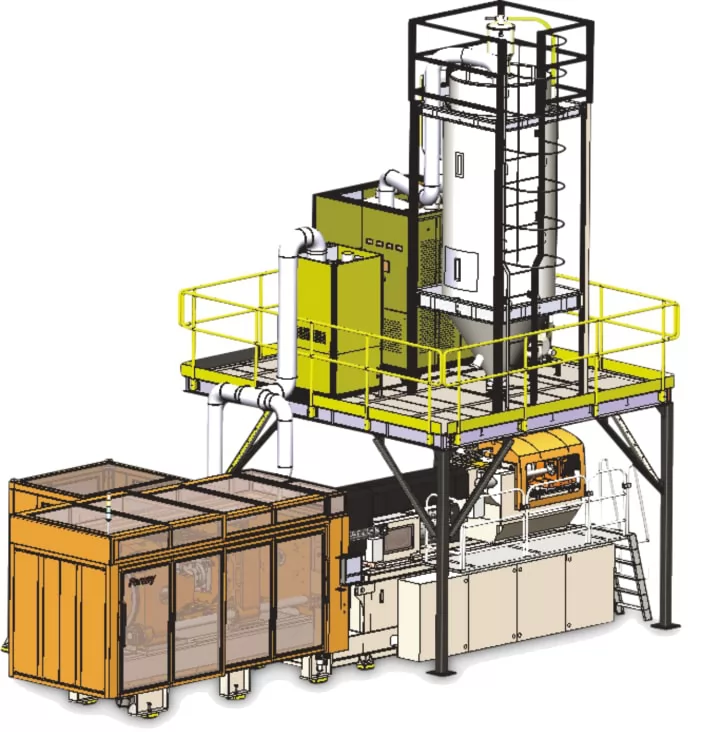

FORAY Precision's F-PET220 high-speed injection molding machine has received recognition and praise from overseas customers for its outstanding cost-effective products and solution services. The equipment was successfully delivered in July 2023, further consolidating FORAY Precision's overseas market. Expand the blueprint.

The overseas customer of this cooperation is the largest local dairy production company, with a market share of 50%, and is the leading company in the South American market. With the recovery and growth of consumption in the market environment and the needs of corporate development, customers responded quickly, expanded the market, added new production lines, and looked for high-output, high-quality PET bottle preform injection molding machine equipment to ensure production needs. Ultimately, customers focused on purchasing " "Made in China" PET preform injection molding machine equipment.

After half a year of investigation and research, FORAY Seiko F-PET220 high-speed injection molding machine has won the favor of customers for its stability, energy saving, high efficiency, high cost performance and comprehensive after-sales service. F-PET220 is comparable to the quality of international brand equipment in terms of equipment configuration, production, efficiency, energy consumption, etc. On this basis, based on the customer's product characteristics and needs, the equipment is customized, optimized and improved to eliminate their doubts and provide them with high-quality equipment. Cost-effective products and solution services, and successfully completed equipment delivery in July 2023.

► Stable, efficient, energy-saving and cost-effective

FORAY Precision has always insisted on innovative research and development to empower customers. It iterated from the first-generation Gpet220 injection molding machine in 2010 to the F-PET high-speed series injection molding machine in 2018, which can carry 48-128 cavity molds and adapt to products of different weights with high efficiency. production needs; after years of consolidation and innovation, F-PET can be said to be "outstanding, efficient and reliable" and has been fully used and recognized in dairy products, mineral water, beverages, edible oils, medical consumables and other fields.

F-PET220 high-speed injection molding machine adopts a two-stage injection molding system. The sol injection is performed simultaneously. The screw length-to-diameter ratio is 1:25, which can better improve the plasticizing capacity. It adopts DAS intelligent system control to realize the equipment drying cycle (including robot) of 3S. And SPC application, whole-process quality traceability and diagnosis make the production process more efficient and smarter.

The production cycle of 28.3G PET bottle preforms for customer products is about 10 seconds, and the operation is stable and smooth, ensuring that the PET bottle preforms are transparent and spot-free, and the pass rate reaches 100%.

The F-PET220 high-speed injection molding machine applies a number of energy-optimizing technologies such as new energy-saving heating rings, combined with servo pump and servo electromelt technology, which reduces energy consumption by more than 20% and noise by more than 30 decibels than traditional models; central hydraulic The station integrates German HYDAC energy storage, filters, and MOOG servo valve control to make the production process more energy-saving and precise.

▶ "Turnkey" project

FORAY Precision's project team follows up and serves overseas customers throughout the process, leveraging its years of injection molding system knowledge reserves, going deep into customer production lines, collecting plant plans, investigating customer products and production needs, providing effective suggestions for water and electricity matching, personnel structure and capability surveys, etc., to provide Customer pre-sales product and solution services, on-sale installation, training and production progress follow-up services, after-sales technical consulting support, special training support, spare parts support and return visits.

Based on comprehensive research on overseas customers, we provide comprehensive planning of space layout from factory layout optimization to project implementation, from PET silos to packaging equipment selection and installation, integrating dryers, dew machines, chillers, etc. from advantageous cooperative brands. , integrated injection molding system one-stop service solution, expands the energy-saving effect of the production line, enhances the overall comprehensive advantages, reduces customer costs such as time, manpower, resources, etc., and helps customers reduce costs and increase efficiency.

► Create a cost-effective PET high-speed injection molding machine made in China "the light of domestic products"

Founded in 2010, FORAY Precision has been deeply involved in the high-speed injection molding system business sector for more than 10 years. The structure of the F-PET220 high-speed injection molding machine exported to the South American market has completely independent technical property rights, and is comparable to the quality of first-line equipment brands at home and abroad. It has experienced The R&D, production and after-sales engineer team support, as well as the absolutely cost-effective service, are highly praised by overseas customers.

As a strategic investment attraction enterprise that builds strong links in Chengdu, Sichuan, FORAY Precision has the responsibility, ability and strength to create and promote the "Light of Domestic Products" brand in the PET high-speed injection molding machine market.