Bottle Cap Mold Manufacturer and Supplier in China

Are you in search of high-quality bottle cap molds to take your production to the next level? Our premium molds are designed for precision, durability, and efficiency, making them the perfect choice for industries like beverages, pharmaceuticals, cosmetics, and more.

From design to manufacturing

Why Foray is an Expert in Cap Mould

We offer an extensive range of injection molds that cater to diverse needs, whether you're producing simple screw caps, flip-tops, or specialized cap designs. Each mold is crafted using cutting-edge CNC machining technology and high-grade materials, ensuring consistent performance, minimal maintenance, and an extended lifespan.

Our bottle cap molds are not only customizable to meet your unique requirements but are also engineered for fast cycle times, helping you boost productivity and reduce production costs. Whether you’re a startup or a large-scale manufacturer, we have the right mold solution to fit your budget and operational needs.

We are a bottle cap mold factory that wholesales a variety of bottle cap molds for various industry applications with different specifications and details.

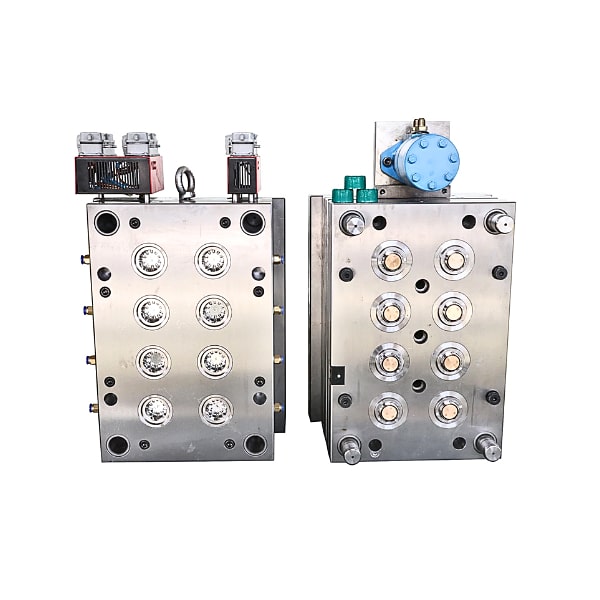

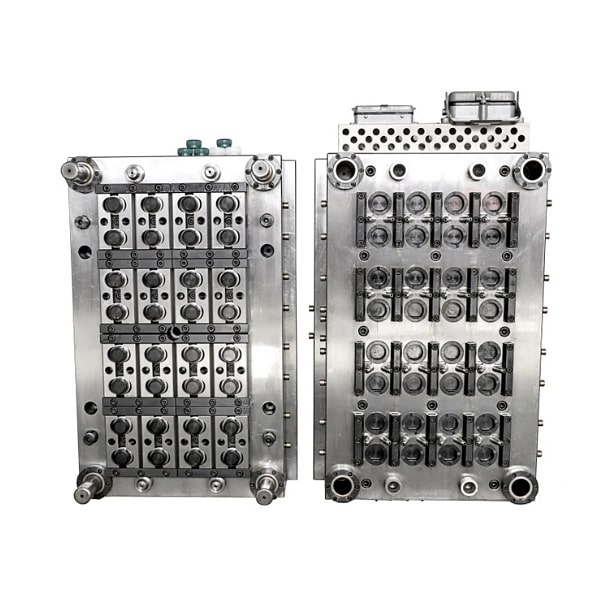

12 Cavity Flip Top Cap Mold with Hot Runner

$20,000.00 - $3,000.00

8 Cavity Cap Mould with Hot Runner and with Motor Structure

$800.00 - $2,000.00

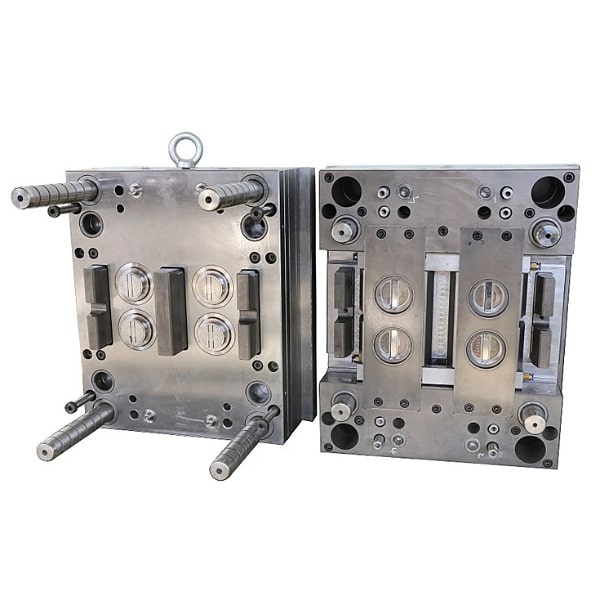

4 Cavity Cap Mould with Cold Runner

$8,000.00 - $12,000.00

8 Cavity Cap Mould with Slider Block and Hot Runner

$15,000.00 - $20,000.00

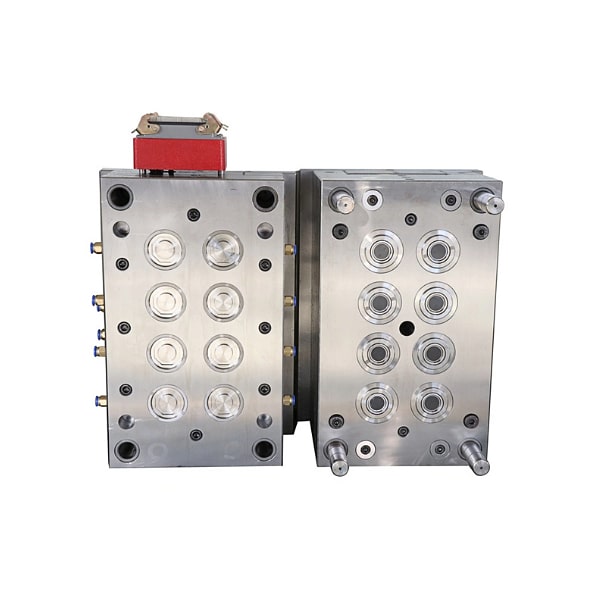

48 Cavities Toothpaste Cap Mold

$1,000.00 - $2,000.00

48 Cavity 5 Gallon Cap Mould with Hot Runner

$1,500.00 - $2,000.00

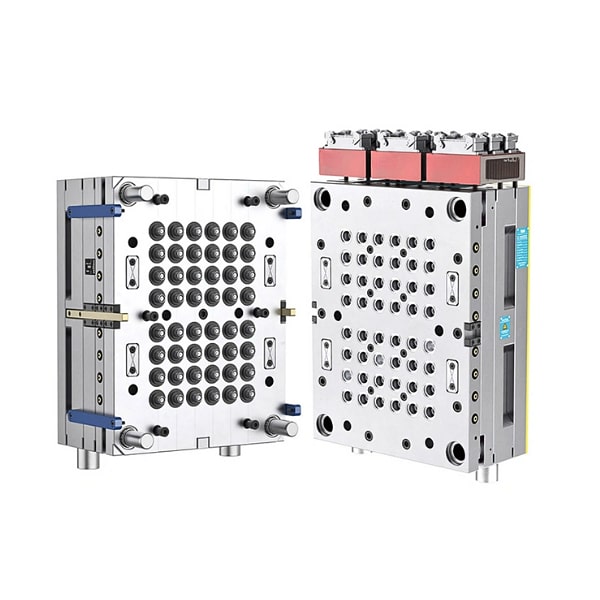

32 Cavity 1881 Pco Cap Mould Hot Runner

$45,000.00 - $60,000.00

24 Cavity 5 Gallon Cap Mold with Hot Runner System

$1,000.00 - $2,000.00

32 Cavity Oil Cap Mold Injection Cap Mould Hot Runner

$1,000.00 - $2,000.00

There are many benefits to working with me, including but not limited to the following:

We provide a variety of plastic bottle cap molds, from 8-cavity molds to 72-cavity molds.

Upload A Design File

You can upload a 3D CAD design file and your specified manufacturing process.

Get Real-Time DFM Analysis

We'll provide you with a real-time DFM analysis with an estimated quote within a few hours.

You Place The Order

Once you have reviewed the potential cost we proposed for your project, you can proceed to place the order.

You Receive The Order

We have a lightning-fast turnaround time and can get done with your order within as fast as 24-hours.

About Foray

Foray (Chengdu Foray Precision Machinery Co., Ltd.), headquartered in Sichuan, China, is one of the well-known Bottle Cap Mould suppliers in China. Provide innovative solutions to customers in the preform packaging market to help customers maximize production while reducing operating costs.

☑ OEM/ODM customized solutions to customize your mold.

☑The company has more than 800 employees and a professional R&D team.

☑ The factory area is 15,000㎡+.

Factory Photos

Factory Photos

Factory Photos

Factory Photos

Browse our wide selection of molds today or contact us to discuss your custom project. Elevate your production process with our reliable and innovative bottle cap molds!

In the world of manufacturing, precision and efficiency are key, and this is especially true when it comes to the production of bottle caps. The bottle cap mold is at the heart of this production process, playing a critical role in ensuring that bottle caps are produced with consistent quality, proper fit, and durability. Whether you're in the business of manufacturing water bottle caps, soda bottle caps, or specialized caps like those used for beverage bottles, understanding the intricacies of bottle cap mold design, cost, and production is crucial for success.

In this comprehensive guide, we will delve deep into everything you need to know about bottle cap molds, covering essential topics such as mold design, the factors affecting bottle cap mold cost, and how to choose the right plastic bottle cap mold manufacturers. Whether you're an industry veteran or new to the field, this article will serve as a valuable resource for navigating the world of bottle cap manufacturing.

A bottle cap mold is a precision-engineered tool used in injection molding machines to produce bottle caps. The mold determines the shape, size, and functionality of the bottle caps, and it is responsible for ensuring that each cap meets strict quality standards.

The bottle cap mold is typically made from high-quality steel or aluminum to withstand the high pressures and temperatures involved in the injection molding process. These molds are designed with cavities, into which molten plastic is injected, cooled, and then ejected as finished bottle caps.

Without a well-designed and properly functioning bottle cap mold, manufacturers risk producing caps that are defective or inconsistent. These defects can lead to significant problems in the packaging process, such as improper sealing, leakage, and contamination. High-quality bottle cap molds ensure that caps are produced efficiently and accurately, leading to lower production costs and higher customer satisfaction.

The design of a bottle cap mold is one of the most critical factors in the production process. A well-designed mold will not only produce caps that fit perfectly on bottles but also minimize material waste and reduce cycle times, which ultimately lowers production costs.

There are various types of bottle cap molds available, each designed for specific applications. Understanding the differences between these molds will help you choose the right one for your needs.

Each of these molds is designed to meet specific functional requirements, and choosing the right one depends on the type of bottle and liquid being sealed.

When designing a plastic bottle cap mold, there are several factors that need to be considered to ensure the final product is of high quality and meets the required specifications.

By carefully considering these factors during the design phase, manufacturers can ensure that their bottle cap mold produces caps that are functional, aesthetically pleasing, and easy to manufacture.

The cost of a bottle cap mold can vary significantly depending on several factors. Understanding what drives the cost will help you budget for your mold and avoid overpaying.

In general, you should expect to pay anywhere from $5,000 to $30,000 or more for a high-quality bottle cap mold, depending on the factors mentioned above.

If you're in the market for a bottle cap mold, there are several factors to keep in mind to ensure you're getting the best value for your money.

By carefully evaluating these factors, you can make an informed decision and purchase a bottle cap mold that meets your production needs.

When choosing a plastic bottle cap mold manufacturer, it's important to select a company that has the expertise and resources to produce high-quality molds that meet your specific requirements.

Some of the top plastic bottle cap mold manufacturers are located in regions known for precision engineering, such as Germany, Japan, the United States, and China. These countries are home to manufacturers with advanced production capabilities and extensive experience in bottle cap mold making. Below are some key players in the industry:

Husky Injection Molding Systems (Canada) – Known for their high-precision molds, Husky offers a range of solutions for plastic bottle cap molds and is a trusted name in the global market.

MHT Mold & Hotrunner Technology AG (Germany) – Specializes in multi-cavity molds for the production of high-volume caps, including water bottle caps and plastic bottle caps. Their molds are renowned for their durability and efficiency.

Taizhou Huangyan Jingtuo Mould Co., Ltd. (China) – A leading manufacturer in the Chinese market, this company produces a wide range of bottle cap molds, including custom designs and high-volume molds for plastic bottle cap manufacturers.

Aero Mould Co., Ltd. (China) – Specializes in cap molds and is known for producing high-quality molds for water bottle lids, plastic caps, and other beverage-related closures. They offer competitive pricing and strong after-sales support.

Otto Männer (Germany) – This company has a strong reputation for precision mold-making and provides custom solutions for complex cap designs, including beverage cap molds.

When choosing a manufacturer, ensure they can meet your production needs in terms of quality, delivery time, and technical support.

Purchasing a plastic bottle cap mold is a significant investment, and it's important to approach the buying process with a clear understanding of your needs and the options available. Below are some steps to help guide you through the purchasing process:

Define Your Requirements: Identify the type of bottle caps you’ll be producing (e.g., water bottle cap mold, beverage cap mold, or plastic bottle cap mold for beverages). Make sure you have detailed specifications for the cap design, including dimensions, thread patterns, and any special requirements for sealing or pressure resistance.

Set a Budget: Determine how much you’re willing to invest in a bottle cap mold. Keep in mind that while higher-quality molds may have a higher upfront cost, they can save you money in the long run by reducing defects, downtime, and maintenance costs.

Research Manufacturers: Look for plastic bottle cap mold manufacturers with a strong reputation and proven experience in producing molds for your specific application. Request quotes and compare the offers based on factors such as price, delivery time, and after-sales support.

Request Customization (if needed): If you require a custom mold design, work closely with the manufacturer’s engineering team to ensure your specific requirements are met. Provide them with detailed CAD drawings and other technical data to ensure precision.

Inspect the Mold: Before finalizing the purchase, ask to inspect the mold (if possible). If you’re buying a used mold, check for signs of wear or damage. For new molds, ensure that the manufacturer has performed quality control checks and tests.

Review Warranty and Support Options: A reliable manufacturer should offer a warranty on their molds and provide support for maintenance, repairs, or spare parts. Having these services in place will reduce long-term operational risks.

By following these steps, you can ensure that you’re purchasing a plastic bottle cap mold that meets your production needs while staying within your budget.

When choosing a bottle cap mold, it's important to understand the differences between molds designed for specific applications, such as water bottle cap molds and molds for other types of bottles, such as soda or pharmaceutical containers.

Material Considerations: Water bottle caps are often made from food-grade plastic materials like polyethylene (PE) or polypropylene (PP), which are safe for contact with drinking water. Other bottle caps, such as those for soda or chemicals, may require different plastic compounds to meet pressure, safety, or durability standards.

Sealing Requirements: A water bottle cap mold is typically designed to ensure an airtight seal, which is essential for preventing leaks and contamination. In contrast, caps for carbonated beverages must be designed to withstand pressure from carbonation, requiring a stronger, more secure thread design.

Thread Patterns: Water bottles typically use a simpler thread design, as they don't require the tight seal needed for pressurized beverages. Caps for soda or sparkling water require a more robust thread design to prevent the cap from loosening under pressure.

Cap Design Features: Water bottle caps often feature tamper-evident seals or flip-tops, which are designed to keep the water secure and prevent tampering. In comparison, soda bottle caps may feature a more rigid design to maintain bottle pressure.

Understanding the specific requirements of your product will help you choose the right mold for your application.

Cap mold making is a complex process that requires precision and attention to detail. There are several common issues that can arise during the manufacturing process, but with the right approach, these problems can be solved.

Warping: This occurs when the bottle caps come out of the mold deformed or warped, which can prevent them from sealing properly. Warping is usually caused by uneven cooling during the molding process.

Solution: Ensure that the mold is equipped with an efficient cooling system to promote uniform cooling of the plastic material.

Flash: Flash is excess plastic that forms along the parting line of the mold, creating unwanted material that must be trimmed off. It is caused by poor mold design or insufficient clamping force during injection.

Solution: Improve the mold design and ensure the injection machine is applying the correct clamping pressure to prevent flash from forming.

Short Shots: Short shots occur when the mold cavity is not fully filled with molten plastic, resulting in incomplete or defective bottle caps.

Solution: Ensure that the injection machine is operating at the correct pressure and temperature, and that the plastic material is flowing evenly into the mold cavities.

Ejection Marks: These marks occur when the bottle caps are ejected from the mold with visible imperfections on the surface.

Solution: Optimize the mold design to allow for smooth ejection, and adjust the ejection system to reduce pressure on the caps during removal.

By addressing these common issues during the design and manufacturing process, you can ensure that your bottle cap mold produces high-quality, defect-free caps.

Proper maintenance is essential for extending the life of your plastic bottle cap mold and ensuring consistent production quality. Regular maintenance can help prevent defects and reduce downtime.

Clean the Mold Regularly: Dust, debris, and plastic residue can accumulate in the mold cavities over time, leading to defects in the caps. Regular cleaning will prevent buildup and ensure smooth operation.

Inspect for Wear and Tear: Check the mold for signs of wear, such as scratches or dents in the mold cavities. These imperfections can affect the quality of the caps and should be repaired promptly.

Lubricate Moving Parts: Ensure that all moving parts of the mold, such as ejector pins and slides, are properly lubricated to prevent friction and wear.

Check the Cooling System: An efficient cooling system is essential for maintaining cycle times and preventing warping. Regularly inspect the cooling channels for blockages or leaks.

Replace Worn Components: Over time, certain components of the mold, such as ejector pins or cavity inserts, may wear out and need to be replaced. Keep spare parts on hand for quick replacements.

By following these maintenance tips, you can extend the life of your plastic bottle cap mold and ensure consistent production quality.

The world of bottle cap mold technology is constantly evolving, with advancements in materials, design, and production techniques leading to more efficient and cost-effective solutions. As sustainability becomes a growing concern in the packaging industry, manufacturers are also exploring new materials and designs that reduce plastic waste and improve recyclability.

In the future, we can expect to see more innovations in cap mold making, such as the use of lightweight materials, advanced cooling systems, and automated production processes. These advancements will help manufacturers produce bottle caps more efficiently while reducing their environmental footprint.

For companies looking to stay competitive in the bottle cap manufacturing industry, investing in high-quality molds, working with experienced plastic bottle cap mold manufacturers, and staying informed about the latest technological advancements will be key to success.

By understanding the complexities of bottle cap molds and implementing best practices in design, production, and maintenance, manufacturers can ensure that they produce high-quality, reliable caps that meet the needs of consumers and industry standards.