If you're running a small business and looking to enter the world of plastic manufacturing, investing in the right preform injection molding machine is crucial for success. Preform injection molding machines are essential for creating preforms, which are the foundation of the bottle manufacturing process. These machines are used to inject molten plastic into a mold cavity to form the preform, which is then stretched and blown into a final shape. For small businesses, choosing the right machine can make a significant difference in production efficiency, cost-effectiveness, and overall product quality.

In this guide, we’ll explore the best preform injection molding machines for small businesses in 2024. We’ve compiled a list of top-rated machines that cater to different needs, from budget-friendly options to those designed for high-speed production. Whether you're just starting or upgrading your machinery, this list will help you find the best injection molding machines for small businesses.

After in-depth research, we provide a brief overview of reliable and competitive PET preform injection molding machines. Factors we consider include experience, time in the industry, employee capabilities, production capabilities, achievements, product quality, and more.

Delivery Address: China

Overview

Foray's preform injection molding machines offer the perfect balance of quality and cost-efficiency, allowing small businesses to compete with top-tier European models at a significantly lower investment. These PET injection machines are designed to meet the highest standards of performance, delivering exceptional quality, increased productivity, and ease of maintenance—all while ensuring sustainability.

Engineered with precision, the Foray preform making machine features an optimized template bracket design that supports molds with 12 to 96 cavities. The incorporation of servo-controlled valves for mold opening and ejection pin functions ensures smoother, more accurate operation, enhancing the machine's overall stability and performance.

With over a decade of industry experience, Foray's injection molding systems have continuously evolved to offer small businesses the best injection molding machine in 2024. The high-performance platform is ideal for producing high-quality preform parts, providing maximum throughput, outstanding reliability, reduced maintenance needs, and improved uptime. Foray’s commitment to innovation guarantees a cost-effective solution for companies seeking to scale their production without compromising on quality.

Main Series:

Delivery Address: Guangdong, China

Overview

Since its inception in 2000, Powerjet Plastic Machinery Co., Ltd. has been a pioneer in the development and manufacturing of plastic preform injection molding machines and extrusion blow molding machines. With over 10,000 successful installations of bottle injection molding machines worldwide, Powerjet has built a reputation for delivering innovative and reliable solutions for businesses across the globe.

Powerjet’s preform injection molding machines are engineered for efficiency, with a cycle time reduction of 3 to 5 seconds, resulting in a 30% reduction in production costs. These PET injection machines are specifically designed with a high-performance PET screw, ensuring the production of superior-quality preforms with minimal waste.

Whether you're a small business looking for cost-effective solutions or a large-scale operation, Powerjet offers the best injection molding machine in 2024 to meet your production needs. Their machines are built to optimize productivity, reduce energy consumption, and deliver long-lasting performance, making them a trusted choice for businesses worldwide.

Main Series:

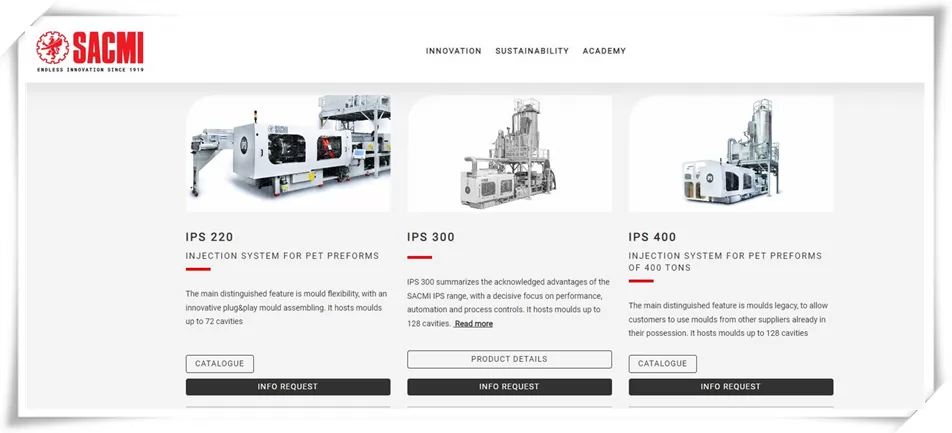

Delivery Address: Imola, Italy

Overview

SACMI is a globally recognized leader in the manufacturing of preform injection molding machines, holding a strong fifth position in the worldwide market. With a commitment to innovation and high-quality standards, SACMI has become a trusted name in the industry, providing cutting-edge preform injection molding solutions to meet the evolving needs of customers.

SACMI's preform injection molding machines are engineered with advanced technologies, including FEM structural analysis, which optimizes mechanical inertia and enhances resistance to mechanical stress. The machines feature a hydraulic actuator equipped with a customized digital servo valve, ensuring ultra-fast lock-to-lock times and significantly reducing preform cycle times. This results in improved efficiency and productivity, making SACMI’s solutions ideal for businesses seeking to improve their manufacturing processes.

As a leading provider of the best injection molding machines in 2024, SACMI continues to focus on delivering high-quality performance, reliability, and customer service, helping small businesses and large manufacturers alike stay competitive in the market.

Main Series:

Delivery Address: Italy

Overview

SIPA is a global leader in the development of advanced solutions for PET preform manufacturing, offering a wide range of machinery designed to meet the diverse needs of the packaging industry. With two main series of preform injection molding machines, SIPA provides tailored solutions that address the specific requirements of different sectors within the global packaging market.

Their XFORM platform, available in capacities of 250, 350, and 500 tonnes, is an ideal choice for the cost-effective production of PET preforms using conventional injection molding. Capable of running molds with up to 200 cavities, the XFORM machine stands out for its high energy efficiency, low maintenance costs, and versatile compatibility, allowing it to accept molds from any manufacturer.

As a trusted supplier of preform injection molding machines, SIPA continues to lead the way in innovation, providing solutions that help businesses—both large and small—optimize their production processes. Whether you're looking for small business injection molding machines or scalable solutions for larger operations, SIPA offers the best injection molding machines in 2024 to meet your needs.

Main Series:

Delivery Address: Canada

Overview

Husky preform injection molding systems lead the industry in maximizing productivity, minimizing part variability and reducing maintenance, resulting in the lowest total production cost.

Their latest generation HyPET®5e, HyPET®5e+ and HyPET®HPP5e series systems maximize throughput, with capacities up to 110,000 preforms per hour, while reducing part variability and improving part quality. Expect them to deliver millions of repeatable cycles without failure, faster and more efficiently than any Husky system in history.

Main Series:

Delivery Address: China

Overview

Since its establishment in 2005, Unique has been committed to providing comprehensive PET bottle preform injection molding solutions and personalized customization services to customers around the world to meet the diverse needs.

Their UPET series injection molding machines adopt a hybrid clamping method, which perfectly guarantees high precision and short cycle time. Control system - through cooperation with Siemens, closed-loop control of the injection speed and holding pressure of the entire injection process is achieved.

Main Series:

Delivery Address: China

Overview

NPC Precision Machinery has rich experience in various types of PET bottle preform manufacturing technology. The PET preform injection molding machine they designed provides optional options for preforms or other PET products. They will review all factors such as: raw material PET dehumidification, additive color mixing, production capacity, stable operation, and even connection with the blow molding machine or other next steps, then NPC will provide you with a professional turnkey solution that fits your budget and requirements .

The PET bottle preform injection molding machine produced by their company is suitable for the molding of bottle preforms for mineral water, carbonated drinks, juice, edible oil, medicine cans, lotions, cosmetic packaging containers and other products.

Main Series:

Delivery Address: China

Overview

The FCS preform injection molding machine mainly produces 24 to 96 preforms. It is equipped with electric feeding to form a double loop with the same action (mold opening and feeding), and the molding cycle is shortened by about 4 seconds to 6 seconds. It can be used in conjunction with molds, blowing, filling, packaging and other equipment to provide customers with solutions to their entire factory needs.

This series of products is suitable for producing various PET bottle preforms, such as water bottles, hot-fill bottles, edible oil bottles, wide-mouth bottles, 5-gallon large bottle preforms, etc.

This equipment is a PET bottle preform equipment, suitable for mineral water, carbonated drinks, juice, edible oil, medicine bottle lotion, cosmetic packaging containers, etc., with a clamping force of 90 tons-800 tons.

Main Series:

90 tons-800 tons Preform Injection Molding Machine

Delivery Address: China

Overview

Huayan specializes in the production of PET/PP preform injection systems, including machines and molds, and widely serves PET packaging applications such as beverages, edible oils, food, pharmaceuticals and cosmetics.

On the basis of maintaining economy and applicability, Huayan preform injection molding machine has carefully adjusted the cycle time, mechanical strength, product quality and operating cost of the equipment through a series of optimized designs. It can provide customers with more economical operating costs and produce high-quality preforms. This series of models has high flexibility and can meet the requirements of different production volumes.

Main Series:

Delivery Address: China

Overview

CLF preform injection molding machine strives for stable development in various fields, from the requirements for machine quality and strong clamping force to the combination of high-tech European and Japanese microprocessor controllers. The entire motor adopts German Siemens control system and servo motor, allowing CLF is able to create innovative structural designs and become an industry leader.

Main Series:

230-6000 tons Preform Injection Molding Machine

We are an injection molding machine manufacturer and supplier from China, specializing in providing reliable preform injection molding machines to small and medium-sized enterprises.

Investing in the right preform injection molding machine is a key step in growing your small business and enhancing your production efficiency. Whether you prioritize energy efficiency, speed, precision, or affordability, the machines listed above are some of the best options available in 2024. When selecting an injection molding machine for your business, consider factors such as production volume, material compatibility, and the specific needs of your operation.

If you need a professional technical team to make the most reasonable suggestions for your project, then you can send an email to communicate with our engineers. We will give you free and reasonable advice based on your needs. Welcome to visit our official website!

Top 10 Preform Mold Manufacturers in the World【2024 List】

How Much Does a Preform Injection Molding Machine Cost?

How to Choose PET Bottle Preform Mold